TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Maximum and Minimum PCB Sizes at Bittele Electronics

PCB designs trend smaller and smaller each year, but just how small can your boards get when you work with Bittele Electronics for your PCB Fabrication project? That is a key question in an industry that prioritizes small form factor, but many of our clients also tend to wonder about the maximum PCB size for their high-power designs and control panel applications. There are in fact a few important factors to consider when it comes to PCB sizing, large or small, in addition to the absolute maximum and minimum dimensions.

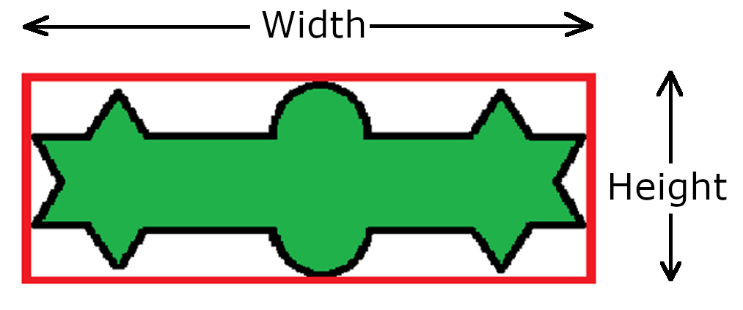

In all cases, individual PCBs are routed from a larger panel of substrate. Bittele can fabricate PCBs of any shape, but the dimensions must be measured in terms of the smallest rectangle that can contain your PCB design. In other words, the height must be measured as the longest vertical distance on the shape, and width as the longest horizontal distance. These dimensions give the effective surface area of your PCB design.

Small-Size PCBs

Bittele uses high-precision PCB fabrication devices that are capable of manufacturing PCBs as small as our clients require; however, clients should be aware that Board Outline tolerance will become more significant as the overall board size becomes very small. Our standard tolerance for board outline is ±0.15 mm (6 mil).

Although we do not place an absolute minimum on PCB dimensions, please note that PCBs with a side less than 2” in length will likely require some additional tooling cost and PCB Turnaround Time. For very small boards, with both dimensions close to or under 2”, this is due to the extreme care that must be taken in handling and fabricating these boards with allowable tolerance. In many cases, a custom jig will be designed and built to ease the fabrication and assembly of such small PCBs. For very narrow boards, with one long side and one side less than 2”, the extra cost and lead time is required to build supports under the board during fabrication and assembly to ensure that the PCBs are not damaged during production.

Large-Size PCBs

Our standard PCB substrate panels are 19.7” by 31.5”, making this the absolute maximum size for a single PCB if we use the entire panel. Similar to small-size PCBs as discussed above, these absolute maximums are not the only dimensions to consider when designing a large PCB for fabrication.

Any board with one or both dimensions greater than 20” will likely incur some additional cost and lead time. As discussed for long and narrow PCBs in the preceding section, large PCBs will require supports to ensure their mechanical integrity during fabrication. The same goes for PCBs with an effective surface area of 100 square inches or larger. Size concerns also extend to the PCB Assembly Process, where any board with a side longer than 14” will likely be subject to some additional cost.

Related Articles:

- Small Circuit Boards - What Is the Smallest PCB Size That Bittele Can Fabricate

- What is the Maximum Panel Size for PCB Printing?

- The Sizes and Usable Areas of PCB Panels

- Max and Min Dimensions for PCB Fabrication Services

- Large Printed Circuit Boards – What is the Largest PCB Size that Bittele Can Fabricate?

Please briefly describe the information you are seeking in the search bar below.

English

English