TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Rigid FR-4 PCBs

Of the many PCB Laminate Materials available on the market today, Rigid FR-4 is by far the most popular selection for all sorts of different PCB projects. This is due to the robust and versatile nature of FR-4 material, in terms of both physical and electrical characteristics, as well as the relatively low cost of this material in comparison to its many strengths. In fact, of all the materials used in PCB Fabrication, the raw laminate material has the most significant impact upon both the cost and the PCB & Assembly Turn Time of the PCB Assembly Process. With material selection being so clearly important, and FR-4 being so ubiquitous in the industry, we at Bittele Electronics want to ensure that our clients are well informed regarding all of the options and properties that FR-4 materials provide.

First and foremost, there are indeed multiple options for FR-4 PCB material; this is a common misconception among clients who are just getting started with professional PCB design and development. In order to discuss these options, we must first cover the basic parameters of PCB Laminate Materials:

Tg – Glass Transition Temperature – The temperature, in degrees Celsius, at which the hard, glassy laminate material transitions into a softer, malleable form.

Td – Decomposition Temperature – The temperature, in degrees Celsius, at which the laminate experiences chemical decomposition.

Dk – Dielectric Constant – Also commonly referred to as εr in Electromagnetics, the dielectric constant describes the relative permittivity of the material, which can be thought of as the material’s ability to store electrical energy in the form of an electric field. A lower Dk value is normally preferable for electrical insulation, but a higher Dk value is often required for higher frequency RF PCBs.

Df – Dissipation Factor – Describes the rate at which energy is dissipated, or lost, in the material for a specific oscillation.

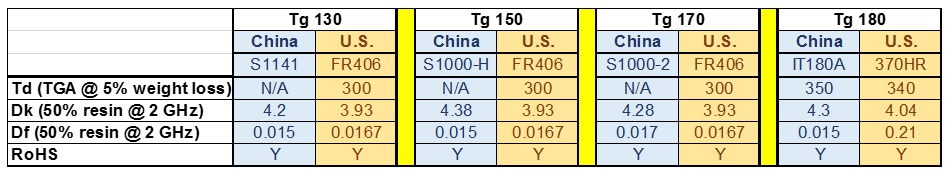

The chart below shows the values of these basic parameters for each of the common FR-4 variants, as well as their local counterparts for overseas manufacturing.

Our default material for manufacturing is a TG-140 FR-4 variant, with Td, Dk, and Df values matching that of the Tg-130 material listed above. We offer the High TG PCB Materials listed above at some additional cost, but no additional turnaround time is required.

The final decision to make with regard to your FR-4 material is the Copper Weight, which describes the thickness of the copper cladding around the insulating FR-4 in terms of ounces per square foot. We offer many options for copper weight, from 0.25 oz. (0.35 mil / 8.75 µm thickness) up to 4.0 oz. (5.6 mil / 140 µm thickness) or more. Copper weights of 1.0 oz. or below are included as part of our PCB Options at a Standard Price, so you never have to worry about unnecessarily paying more for standard 1.0 oz. copper. It should be noted briefly that Heavy Copper PCBs, requiring 4.0 oz. or above, will require special attention from our production engineers, and might incur significant additional cost and lead time for your project. It is a good idea to send in your heavy copper projects as early as possible for quotation to ensure an adequate timeframe for their special attention.

Bittele Electronics is continuously working to ensure that all of our clients are well informed with regard to every aspect of their PCB projects. If you still find yourself unsure about any aspect of FR-4 material, or send along your PCB Design Files for an official quotation today, please Contact Us via email at sales@7pcb.com, or call our offices toll-free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English