TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

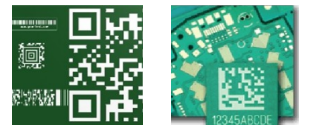

Laser Engraving Services

Bittele Electronics offers its clients a laser engraving service that enables the direct marking of serial numbers, QR or DM codes, and alphanumeric texts on printed circuit board surface. This innovation enhances both production and field traceability of PCBs and PCB assemblies, supports efficient inventory management, and improves overall quality control.

Laser Engraving Overview

Laser engraving uses a noncontact, high-powered laser beam to etch permanent markings onto PCB surfaces without mechanical stress or deformation. Unlike ink or sticker labeling, laser engraving creates durable, high-contrast markings that are resistant to wear, chemicals, and environmental factors offering an ecofriendly and consumable free alternative.

Main Applications

Laser engraving on PCBs is primarily used for:

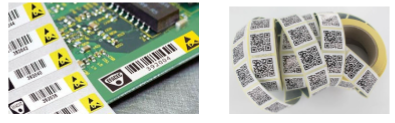

- Traceability: Assign unique IDs to PCBs/PCBAs for supply chain processes to ensure that each unit can be individually identified and traced, facilitating quality control, inventories and accountability.

- Quality Assurance: Permanent markings ensure that each unit can be traced back to its production batch, aiding in defect analysis and process improvements.

- Production Efficiency: The markings help to modernize the process by avoiding manual labeling, reducing effort, cost and possibility of errors.

Advantages Over Traditional Labeling Approaches

Laser engraving offers several advantages over traditional labeling methods such as ink printing or adhesive labels:

- High Precision and Resolution: Laser engraving can produce marks with micrometer-level accuracy, making it ideal for intricate designs. This high level of precision ensures that even the smallest details are clearly visible and readable.

- Durability: The marks are permanent and resistant to wear, chemicals, and environmental factors, ensuring longevity. This makes laser-engraved labels suitable for harsh environments where other labeling methods might fail.

- Non-Contact Process: The laser does not physically touch the PCB, reducing the risk of mechanical damage and eliminating mechanical stress on the board. This is particularly important for delicate or densely packed PCBs where physical contact could cause damage.

- No Consumables: Unlike ink printing, laser engraving does not require consumables, making it more cost-effective and environmentally friendly. This reduces the need for regular maintenance and replacement of consumable materials, leading to lower operational costs.

Design Considerations

The engraving quality depends on the PCB surface material (FR4, aluminum, ceramic, etc.). Some coatings or soldermask ink color may affect the contrast of codes. Adjustments to engraving depth or board color selection may be used to enhance readability.

Laser engraving equipment supports a broad range of marking dimensions, however, for simple QR and DM codes, we recommend a minimum of 4x4mm of reserved space on the PCB. By default, Bittele will add white ink block on PCB which allows us to engrave the code on top for greatest contrast before soldering.

We will confirm the exact location of the block/code during DFM/DFA stage.

By adding laser engraving to our portfolio, Bittele Electronics strengthens its service offering with advanced solutions for product traceability and identification, reinforcing our dedication to innovation, quality, and customer satisfaction.

For more information about our capabilities or to send us your Design Files for an official quotation, please feel free to Contact Us any time! We can be reached via email at sales@7pcb.com or call at 1-416-800-7540.

English

English