TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

DFA Validation for PCB Assembly

Efficiency and customer satisfaction are core principles here at Bittele Electronics, which is why we go the extra mile to ensure that your PCB project is made flawlessly the first time. In addition to our various testing methods, such as Electrical Netlist Testing, multi-stage Visual Inspection, X-Ray Inspection, AOI Testing, ICT (In-Circuit Testing), and FCT (Functional Circuit Testing), we also provide independent verification at the very beginning of the PCB Assembly Process, during a stage that is known as the DFA Check. This article will give a brief explanation of the DFA Check’s purpose and general procedure, with the aim of allowing our clients more control over the efficiency of their projects by keeping our methods in order during the design phase of a project. For a comprehensive account of DFA Checking, along with all of our relevant tolerances and guidelines, please see our DFA Guidelines document.

DFA stands for “Design for Assembly”, which refers to a specific method of product design that takes into account not only the functionality of a finished product, but also the cost and efficiency of the PCB Assembly Process for that product. Bittele will always pass these savings along to our clients, so a PCB layout that was created using strong DFA principles will likely see benefits in its overall quality and shelf life, in addition to savings in cost and project turn time.

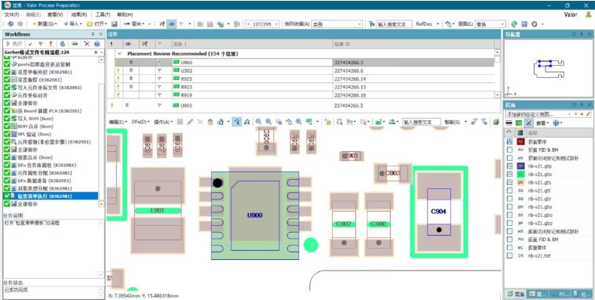

As soon your order is placed with Bittele Electronics, the first stage of production is for both DFM Checking and DFA Checking to begin. The DFA Check process continues throughout our process since our Parts Procurement service occurs concurrently with PCB Fabrication. Our highly trained Quality Assurance engineering team will raise any potential issues that they notice during any stage of DFM or DFA Checking with you immediately so that a resolution can be resolved as soon as possible. The main categories included in our DFA Check process are:

- Footprint vs. Land Pattern comparison

- Reference Designator cross-check between the BOM (Bill of Materials) and Centroid files

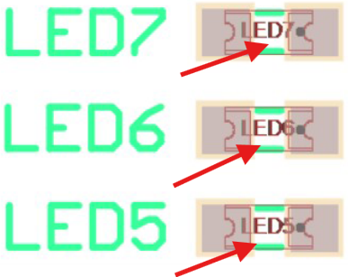

- General Silkscreen Clarity

- Rotation data consistency (Zero Orientation check)

- Incoming Material Inspection for electronic components

- Design placements satisfy Minimum Part Spacing rules

- Any other concern or Ambiguity in PCB Design

The topics above link to our more in-depth articles about many of the procedures in question, but if you find yourself with any further questions, please feel free to Contact Us. You can reach us via email at sales@7pcb.com, or toll-free at 1-888-812-1949.

English

English