TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Does Your PCB Design Have To Include Reference Designators?

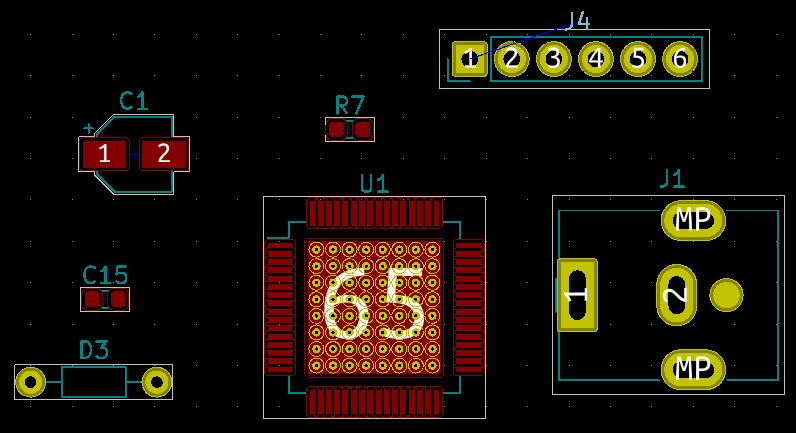

For some PCB Designers, reference designators are something of an afterthought, but if they are neglected too much, these innocuous labels can begin to cause trouble during PCB Assembly. Your CAD PCB Layout software likely applies reference designators automatically, and they are transferred onto your Bill of Materials (BoM) without any special attention required. The automatic nature of this process can make it easy to overlook the importance of reference designators, so the intent of this article is to highlight their importance in Complete PCB Assembly, and to give Bittele’s clients a clear picture of exactly what is required. With this information at hand, you will be able to make sure that your PCB design is clear and understandable before PCB Fabrication begins, and thereby avoid delays and other mishaps that might result from unclear labelling.

During the PCB Assembly Process, reference designators are required for a variety of different steps. Most notably, they are included in the Centroid file, and through that data they allow our Pick & Place machines to match the parts on your BoM to their actual coordinates on the PCB. Reference designators also play an important role in the Visual Inspection and Automated Optical Inspection (AOI) processes, since they allow us to verify that each part is placed in the correct location. Furthermore, these labels allow for easier communication with our production team in the case that they have a question about your design. For all of these reasons, we consider reference designators to be one of our Essential PCB Design Rules.

Some of our clients have asked about whether reference designators are even necessary at all for their designs. This question usually comes from clients who are working on High-Density Interconnect (HDI) boards, where space on the PCB is extremely limited, and printing reference designators on the silkscreen layer is simply not possible. We also sometimes hear this question from clients who are concerned with the aesthetics of the PCB itself. In this case, we recommend creating an Assembly Drawing to submit along with your PCB Design Files. This way, you can include proper reference designators in your Centroid and BoM files, but keep your silkscreen layer clear, and our Quality Assurance team can still double-check your Assembly Drawing for verification purposes.

We do often catch small design errors during our initial verification stages, or even during the quote stage, where reference designators are concerned. Mainly, we see mismatches between the BoM and the Centroid, or repeated designators for different parts; this latter issue is most commonly seen in panelized designs. Bittele’s quality management and customer service teams are very adept at catching these types of errors before production begins, but the confusion can be avoided entirely if clients develop a Consistency in Reference Designator design.

If you find yourself with any further questions about the reference designators in your PCB design, please feel free to Contact Us any time to ask! Bittele Electronics is a full-service PCB specialist, providing high-quality PCB Assembly in Canada for our clients worldwide. You can reach us at sales@7pcb.com, or toll-free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English