TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

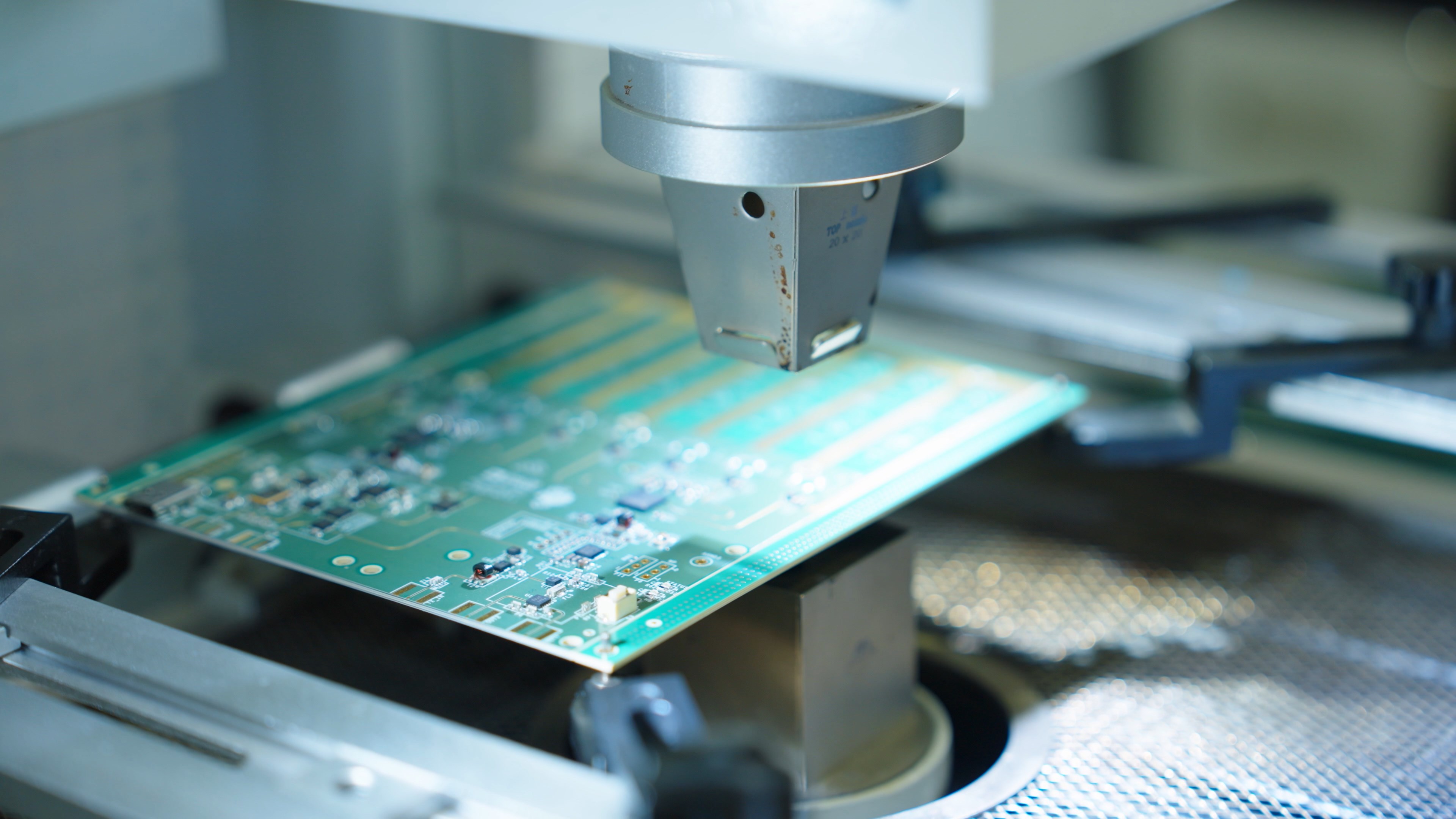

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

What types of products can SMT be applied to?

SMT (Surface Mount Technology) is one of the most important assembly technologies in the current electronics manufacturing industry and is widely used in the manufacturing process of various electronic products. Today, we will focus on the types and characteristics of SMT application products to help you further understand this important field.

1. SMD components

Chip components are the most widely used type of products in SMT technology. They are small in size, light in weight, and easy to mount automatically. In addition, since the pins of the components are exposed, they are easy to install and repair unconventionally. Common chip components include resistors, capacitors, transistors, etc., which are widely used in consumer electronic products such as mobile phones, tablets, and TVs.

2. IC packaging

IC (Integrated Circuit) is an indispensable core component in modern electronic products. SMT technology is of great significance in IC packaging. Common IC packaging types include DIP (Dual in-line package), SOP (Small Outline Package) and QFP (Quad Flat Package). These packaging types are widely used in different electronic products, such as computers, communication equipment and automotive electronics.

3. Connectors

Connectors are important components used to achieve circuit connections in electronic products. In SMT applications, the types of connectors vary greatly, such as USB interfaces, HDMI interfaces, and SIM card sockets. SMT connectors are easy to automate and install, and are widely used in various consumer electronic products and industrial control equipment.

4. Display Module

Display modules are important modules used for image or text display in various electronic products. In SMT production, common display modules include LCD (Liquid Crystal Display), OLED (Organic Light Emitting Diode) and TFT (Thin Film Transistor). These display modules have important application prospects in mobile phones, televisions, car navigation systems and other products.

5. Sensor

Sensors play an important role in sensing and controlling modern electronic products. SMT technology makes the manufacturing of sensors more efficient and reliable. Common sensor types include light sensors, temperature sensors, and air pressure sensors. These sensors are widely used in mobile phones, smart homes, automotive electronics, and other fields, providing products with various intelligent sensing and control functions.

Through the above analysis of SMT application product types, we can see that SMT technology has penetrated into all aspects of electronic product manufacturing. SMD components, IC packaging, connectors, display modules, sensors and other product types play an important role in various industries. With the continuous advancement of technology, we believe that SMT application products will become more diversified and intelligent.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English