TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

PCB Connectors and Terminals

For any PCB to accomplish its purpose, each and every piece of the design must work in harmony, from the most complex pieces right down to the simple connectors. In the design process of any PCB, there are many considerations and judgements to be made around how the circuit will function, but some thought must still be spared with regard to the circuit’s interface to its environment. After all, once PCB Fabrication and PCB Assembly are finished, nearly every board will have to connect to some sort of external device, be that another PCB, a control mechanism, or simply a power supply. In this article, Bittele Electronics outlines for our clients the effects that common connector types might have on the PCB Assembly Process.

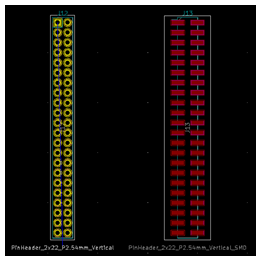

Before we get into a discussion of any specific type of connector, it is important to discuss the general impact of these parts on Turnkey PCB Service. Notably, connectors are one of the few remaining types of electronic component that largely require Through-Hole Device (THD) Assembly, a process that is somewhat more demanding than the more modern Surface Mount Device (SMD) Assembly. For smaller Prototype PCB Assembly runs, Through-Hole Devices can normally be installed by Bittele’s highly skilled Manual PCB Assembly technicians, but larger-scale production runs require a Wave Soldering process be used in addition to our normal Reflow Soldering procedures. Many connectors come in both surface mount and through-hole variants, but connectors that will see repeated connection and disconnection might require the greater durability that often comes with through-hole connector variants.

There is also the area of Parts Procurement to consider when selecting connectors for your PCB project. As with every part on your Bill of Materials (BOM), it is important to ensure that supplier stock levels can meet your requirements before submitting your order to production. One common cause of order delay early in Complete PCB Assembly is insufficient stock on a client’s specialty connectors. For orders including such non-standard connectors and terminals, special arrangements might have to be made in advance with suppliers or component manufacturers to ensure that your parts will be available on time. It is always a good idea to check stock levels of common suppliers such as Digi-Key, Mouser, Arrow, Newark, or Future well in advance of order placement, just to get an idea of where PCB Component Stock Issues might lie.

Rectangular Connectors

The most common type of connectors are certainly the standard rectangular formats, which are composed of protruding pins arranged in a matrix of rows and columns. These connectors are generally lightweight, easy to install, and versatile in their application, which explains their widespread popularity. The main thing to keep in mind, particularly for Volume PCB Assembly, is the method of actual connection to these headers, which normally involves a ribbon cable composed of individual wires with crimped-on contacts inserted into a uniform terminal block.

Prototype PCB Assembly clients generally elect to purchase pre-assembled ribbon cables for their projects, but these solutions can be costly at higher volumes, and some clients will ask Bittele to perform additional PCB Wire Assembly as a result. Of course, we are happy to assist our clients with Wire Assembly on larger scale orders, but clients should be advised that this service will require additional cost and PCB Turn Time, potentially including the purchase of new tools such as proprietary wire crimpers depending upon the nature of the Wire Assembly job in question. Wire Assembly jobs must be quoted on a case-by-case basis since the work involved depends so heavily upon the specifics of the parts and PCB design in question. As such, it is important to get in touch with our PCB Customer Service Experts as early as possible in the process, and send along any preliminary documentation you might have.

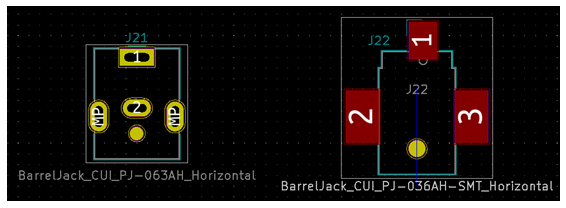

Circular and Barrel Connectors

This category includes most other standard connector types, most of which are used to interface a PCB with a third-party cable or other device. These connectors are generally of no concern for Bittele during the PCB Assembly Process, as they very rarely require Wire Assembly or other auxiliary services. The only potential issue to be wary of with regard to these components is their weight. Some high-quality circular and barrel connectors incorporate a heavy metallic housing, which could drive up the shipping cost of an order beyond regular expectations.

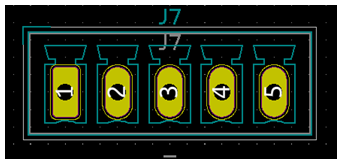

Terminal Blocks

Terminal Blocks refer to connectors with screw or snap terminals for the termination of wires onto a PCB. These types of connectors offer many of the same benefits as standard Rectangular Connectors, in terms of their lightweight nature and ease of installation. Furthermore, these parts avoid the need for crimping and other such time-consuming Wire Assembly procedures.

Of course, there are many types of connectors not fully described by the above categories, but we hope that this explanation will provide our clients with some reference for how their connector selection will affect their PCB orders with Bittele. If you do have any specific questions about connectors for your project that are not covered in this article, please feel free to Contact Us any time! You can reach our team at sales@7pcb.com, or 1-888-812-1949.

Related Articles:

- 9 Common Issues During Component Selection

- Bittele's Quality Control Procedures for PCB Components

- Gold Fingers: A Guide to Understanding Gold-Plated PCB Connectors

- Through-Hole Device (THD) Assembly

- Case study: How to Create a Reflow Profile for a 16-layer, 2mm Thickness PCB with a High Density SMT Connector?

Please briefly describe the information you are seeking in the search bar below.

English

English