TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Non-Conductive Via Filling (NCVF) and Its Advantages

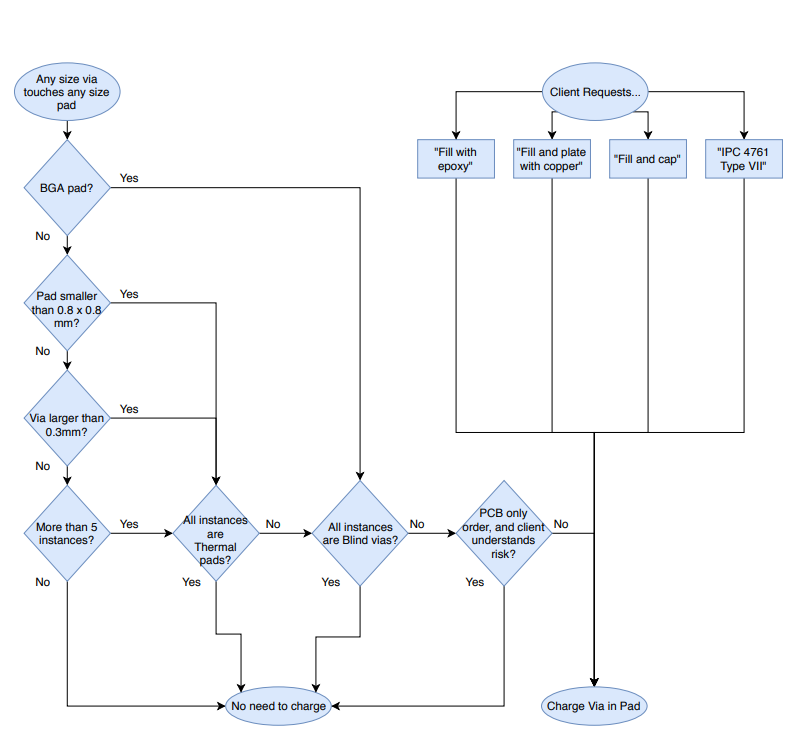

Filled vias can be a point of confusion for some PCB designers. Various different techniques exist for filling a via, depending upon the specifics of the project undergoing PCB Fabrication. If via filling is required for your project, then the technique most suitable for your project will depend upon the exact purpose of the vias in question.

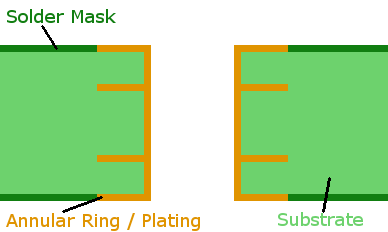

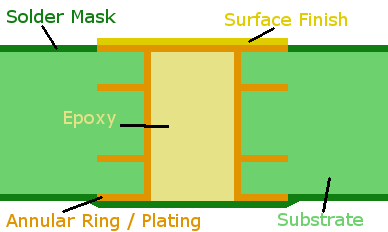

The standard PCB via acts to carry signals from one layer on your PCB to another, but in some instances the transmission of that signal might be disturbed by the physical or electrical properties of the circuit built around the via. For example: simply capping, or “tenting” a via is the process of sealing its top hole with solder mask; If you are looking for a more practical via fill, you really have two options: conductive and non-conductive.

Conductive via filling is used for vias that need to carry large amounts of either heat or current to another layer of the board, as is common in High Temperature PCBs. Non-Conductive Via Filling (NCVF), refers to the process of filling a via with epoxy prior to finishing. This technique is used mainly for Via in Pad designs, in order to prevent excess solder from wicking away from the pad and down into the via hole during Reflow Soldering stage of the PCB Assembly Process.

Via in pad designs are required for a multitude of designs, whether it be the impossibility of escaping your 0.3 mm BGA, or perhaps you have a larger QFP and QFN-type package with a central ground pad that requires perforation by vias for thermal dissipation. The former of these two scenarios will require some additional cost and lead time in order to allow our production team the time to work with the non-conductive epoxy solution. Thermal pad vias, on the other hand, need not be filled at all, so these will not require any additional pricing or lead time.

If you still find yourself with any questions about our policies and procedures, you can get some preliminary pricing from our Online PCB Fabrication Calculator. You can also Contact Us at sales@7pcb.com, or call toll-free to 1-888-812-1949

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English