TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Hot Air Solder Leveling (HASL)

Hot Air Solder Leveling (HASL) is one of the most common types of PCB surface finishes used in the industry today. HASL finishes are composed of solder, with proportions of approximately 63% tin and 37% lead, but HASL can also be used for Lead-Free PCBs, with only minor changes to the process. This finish is applied by first dipping the circuit board into a molten pot of the tin/lead alloy after the Solder Mask has been applied. Next, a Hot Air Leveler (HAL) removes the excess solder, using hot air knives to leave behind only the thinnest possible layer. This remaining layer of solder protects the traces underneath from corrosion, while easing the task of soldering components to the board during the PCB Assembly Process by pre-tinning the pads on the board. HASL is a very cost-effective surface finish compared to other types of finishes, and thus is considered a great choice for general purpose boards.

Lead-Free Hot Air Solder Leveling (LF-HASL) is similar to HASL in appearance and usage; however, the solder in this case contains a mix of 99.3% Tin and 0.6% Copper. This alloy results in a higher melting point for lead-free solder, when compared with leaded solder, requiring a slight modification for the Reflow Soldering process in our Complete PCB Assembly solution. LF-HASL is a replacement for leaded solder, used when a lead-free or RoHS Compliant PCB is required. Please note that a High-Temperature Laminate Material is needed for applying this finish; otherwise, the process is identical.

In the past, HASL was one of the most popular surface finish choices due to its qualities as a low cost and robust solution. Recent fundamental changes in the PCB industry, such as increasing amounts of complex surface mount technology (SMT), have revealed HASL’s shortcomings. HASL is not suitable for use with fine-pitch SMT PCB Assembly due to uneven surfaces being incompatible with fine pitch components. Recently, lead-free LF-HASL became available, but now there are other lead-free options more suitable for a high-reliability product.

Pros

|

Cons

|

|---|

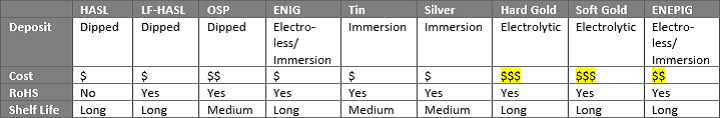

Bittele offers a variety of surface finish options, all for a standard price, including HASL. Please note before ordering that we quote lead-free (LF-HASL) by default; there is no difference in price or lead time between the two. In fact, for your convenience, Bittele offers a selection of no-cost-added surface finish options, as a part of our PCB Options at a Standard Price. The chart below shows basic attributes for each finish we have available.

For more information about our surface finish options, or to get started on your PCB project with Bittele today, please feel free to Contact Us any time! We can be reached via email at sales@7pcb.com, or toll-free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English