TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

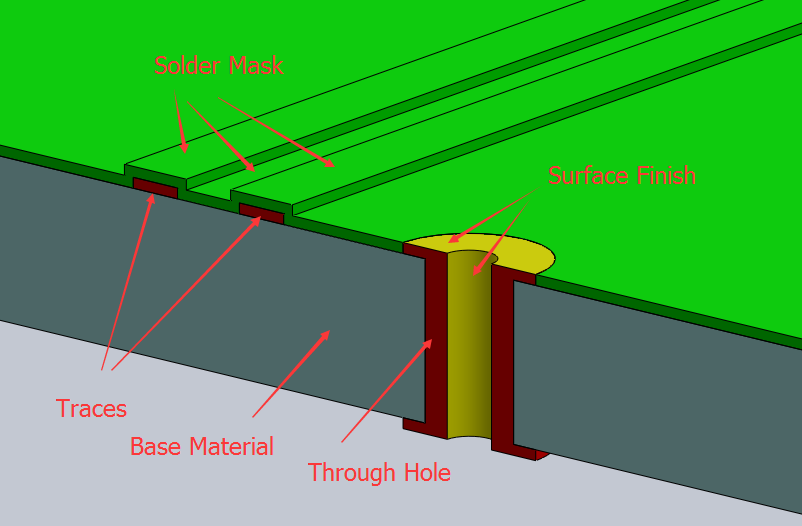

Solder Tinned Pads vs Gold Plated Pads

PCB designers must be selective in their choice of surface finish. If a designer chooses ENIG, their pads will not be tinned with solder, they will instead be gold plated.

It is recommended that designers of PCBs consider what their desired result is, research the options, and make the appropriate choice for their surface finish.

The solution for designers who want solder tinned pads is either HASL or LF-HASL as a surface finish. Things to consider when deciding which surface finish to select include RoHS compliance, shelf life, protection against oxidization and corrosion, and solder-ability. Of course there are many options for surface finish, but HASL and LF-HASL are the only surface finishes that will yield the desired effect if a designer wants solder tinned pads.

One benefit of selecting HASL as the surface finish while fabricating PCBs is all of the through holes get tinned as the board is immersed in molten solder. This provides excellent shelf life and solder-ability. Unfortunately, HASL does not comply with the RoHS directive because the solder used contains lead. LF-HASL is RoHS compliant, but it is otherwise equivalent to HASL in terms of both cost effectiveness and required time.

ENIG provides excellent protection against corrosion and oxidization as well as superb conductivity, while also having the shelf life and solder-ability possible with HASL and the RoHS compliance possible with LF-HASL. This is because the nickel plated copper traces of the PCB have gold deposited on them through an electrolytic process. ENIG is also very cost effective and does not require any additional process time as compared to HASL or LF-HASL.

It is recommended that designers choose ENIG as their surface finish because it is by far the best of the three. However, if the designer is insistent on solder tinned pads, then LF-HASL is recommended over HASL because it is RoHS compliant and completely lead-free. Bittele Electronics Inc. follow the RoHS directive and encourages clients to use lead-free surface finishing materials by making it the same price. Special orders for HASL can be accommodated at the client’s request.

Solder Mask Over Bare Copper (SMOBC) is one of the primary processes of modern PCB fabrication. It is done to ensure that the traces on the PCB have good electrical isolation and to prevent oxidization and short circuits during soldering. The SMOBC process occurs in the early stages of PCB fabrication.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English