TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

ENIG vs HASL : Different surface finish techniques

There are many types of surface finish used for plating the Printed Circuit Boards(PCB). E.g. Organic Surface Protectant (OSP), Immersion Silver (IAg), Immersion tin, Electroless Nickel with Immersion Gold coating (ENIG), and direct gold plating (over nickel). Among them, HASL and ENIG have been dominating the market for decades. HASL had been famous in the past and ENIG is gaining market nowadays. Due to anti lead laws in EU, China, California, etc, demands for ENIG have increased in the past few years.

HASL is less environment friendly than ENIG. Choosing ENIG over HASL, reduces the use of lead and emission from flux and fusing oil. HASL might seem cheaper than ENIG for 2 layer boards but as we go for more layers, the cost for ENIG and HASL plating would be very close to each other.

HASL has a excellent solder-ability and has a good shelf life. ENIG has excellent corrosion resistance, it is good for aluminum wire bonding, excellent for fine-pitch technology, excellent solder-ability and excellent shelf life.

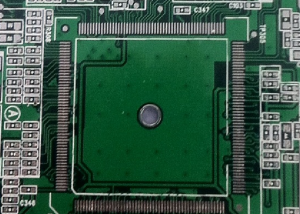

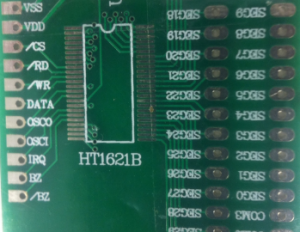

The first picture is from one of my HASL plated boards and the second one is from one of my ENIG plated board. Sorry, the quality of the pictures are not good.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English