TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

V-Score Panelization

Individual PCBs designs are normally replicated into a larger panel for efficiency in PCB Fabrication. This is often the case even for relatively low-volume Prototype PCB Assembly projects, but it is especially important when your project moves into larger-scale production. The good news for clients of Bittele is that you rarely have to worry about panelization and depanelization of your boards, since we handle those details internally. The exception is for those clients who prefer to receive their boards still the panel, rather than fully separated, for testing purposes.

In this case, you have a couple of options to choose from when it comes to the format of the panels you receive. You can choose either Tab Routing or V-Scoring for the depanelization of your individual PCBs. Here we focus just what V-Scoring is, and what to expect if you ask for this treatment on your boards.

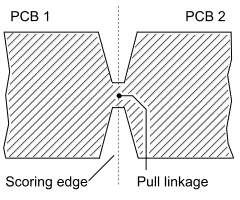

A V-Score refers to a V-shaped grove that is cut into the PCB Material, between each copy of the board in question. Typically, a third of the PCB Thickness is removed from the top of the board, and another third from the bottom, leaving the third in the middle still joining the boards. For Minimum Thickness PCBs, up to about 31 mil, we will generally only apply one-sided scoring.

V-Scores must also be straight lines on the panel, which restricts the shape of the individual boards. This particular restriction has made Tab Routing more popular, as it allows for any shape, while V-Scoring is only viable for square or rectangular PCBs.

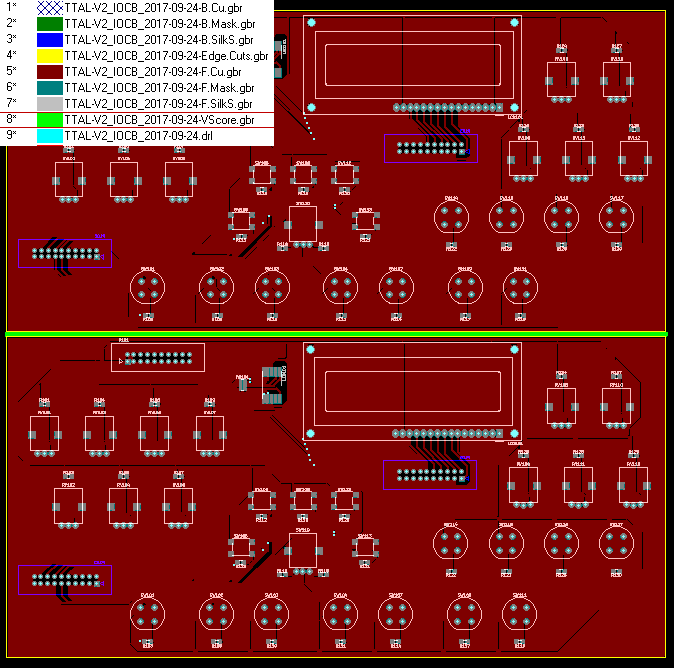

The image below shows the Gerber files for a large control and display board that has been panelized using V-Scoring. You can see the V-Score line in bright green on the Gerber viewer. It is important to be extra careful in following Bittele’s Part-to-Board-Edge Spacing requirements when your design incorporates V-Scoring, so ensure that enough room is left between replications for the V-Scoring process.

If you are considering V-Scoring for your PCB panels, keep in mind that the depanelization of the individual PCBs is not as easy as simply snapping them apart along the V-Score. When we use this type of panelization in-house, we separate the boards using a special cutting tool, and mill down any rough edges. Simply trying to snap the boards apart can place undue stress on your critical components and traces.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English