TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

SMT assembly quality related standards

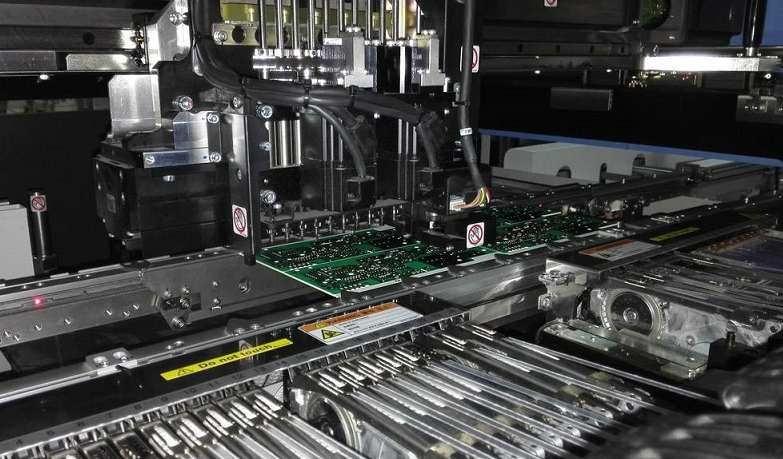

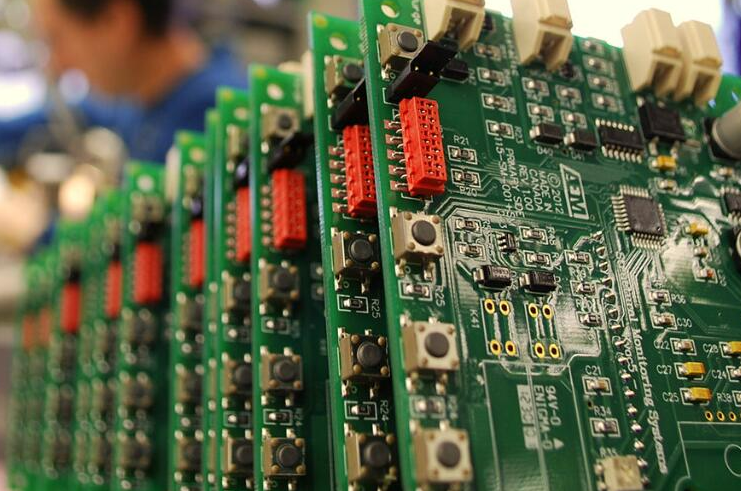

In the context of the development of the electronics manufacturing industry, SMT (Surface Mount Technology) assembly technology has become one of the main manufacturing methods for electronic components. However, the quality of SMT assembly has also received increasing attention. This article will explore in depth the standards and control methods related to SMT assembly quality to help you understand how to improve the quality of electronics manufacturing.

1. The importance of SMT assembly quality

As a key link in the electronic manufacturing process, SMT assembly has a significant impact on the performance and reliability of the final product. High-quality SMT assembly can ensure the working stability, reliability and life of electronic products, reduce the repair and return rate, and improve customer satisfaction. Therefore, it is crucial to formulate applicable SMT assembly quality standards and control methods.

2. Core Standards of SMT Assembly Quality

- Component installation quality standards: including welding quality, component position accuracy, pad quality, etc.

- Welding quality standards: including welding contact performance, welding strength, weld point appearance, etc.

- Welding environment standards: including temperature and humidity requirements, dust-free requirements, anti-static requirements, etc.

- Inspection standards: including welding defect inspection, component defect inspection, welding point inspection, etc.

- Process control standards: including equipment commissioning, operating specifications, process parameter control, etc.

3. Key methods to improve SMT assembly quality

- Strictly control the quality of components: select component suppliers with high reliability to ensure the stable quality of components.

- Strengthen equipment maintenance and care: Regularly inspect and maintain equipment to ensure normal operation of the equipment and reduce failure rates.

- Improve the skill level of operators: Train the skills of operators so that they can master the technical points of SMT assembly and improve the accuracy and efficiency of operations.

- Strictly implement the process flow: operate according to the standard process flow to ensure that the quality of each link is controllable.

- Strengthen quality control and testing: Increase quality control and testing links to discover and solve quality problems in advance and ensure product consistency and stability.

4. The significance of SMT assembly quality assurance

By strictly complying with SMT assembly quality standards and control methods, the quality and efficiency of electronic manufacturing can be effectively improved. Specifically, the significance of SMT assembly quality assurance is reflected in the following aspects:

- Reduce production costs: reduce defective and return rates, and save manpower, material and financial resources.

- Improve work efficiency: reduce repetitive work in the manufacturing process and improve production efficiency and speed.

- Enhance brand image: Provide high-quality products to enhance brand competitiveness and market recognition.

- Increase customer satisfaction: Provide products with stable performance and reliable quality to win the trust and satisfaction of customers.

In summary, the formulation of SMT assembly quality standards and the strict implementation of control methods are the key to improving the quality of electronic manufacturing. Only through scientific and effective quality management can we ensure the stability and reliability of products and enhance the competitiveness of SMT assembly companies in the market competition. I hope this article can provide you with some useful guidance and reference.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English