TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

POP (Part-on-Part) Assembly

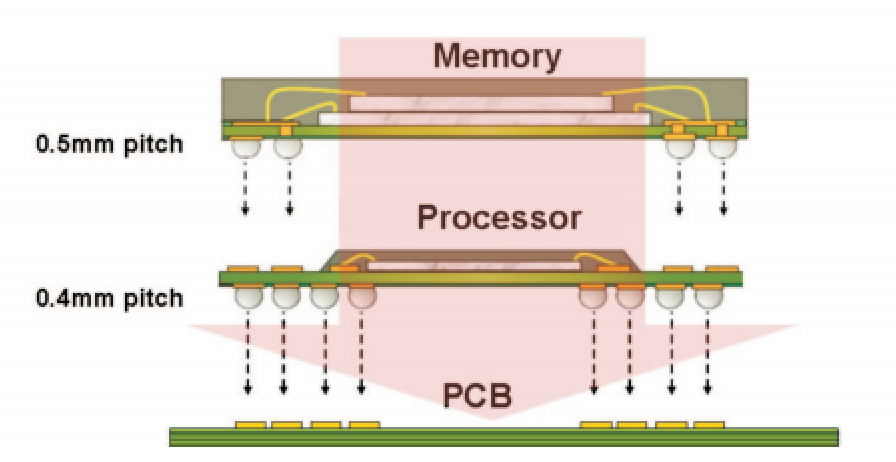

POP technology allows certain components to be stacked on top of one another during the PCB Assembly Process; for example, some advanced processors will have their memory modules mounted directly on top of the main processor package. This technology offers key advantages in miniaturization for many High-Density Interconnect (HDI) designs, but also requires special consideration during PCB assembly, including multiple placement and/or Reflow Soldering cycles. These additional considerations can drive up both cost and lead time for a PCB assembly project.

POP parts are a Complex Component, and unlike simpler packages, POP type parts require solder paste to be screened not only onto the PCB, but also onto the bottom chip. This means an additional step must be performed after the regular paste application, which can be tedious for larger volume orders.

For the reflow soldering procedure, there are two options available:

- Single-Pass Reflow

- Two-Step Reflow

By default, Bittele will use Single-Pass Reflow, since it requires the least amount of additional cost and lead time. In this method, solder paste is applied to both parts, and the processor is placed on the board, and the memory is immediately placed on top. The fully-assembled boards are then reflowed, and inspections are performed.

The only concern with Single-Pass Reflow is around X-Ray Inspection. Since the memory chip sits on top of the processor, the solder in between the 2 chips will likely block the X-Ray image for some of the pins on the processor. We can try to solve this issue by taking 2 X-Ray images; one looking down from the top of the board, and another looking up from the bottom. Still though, it might be difficult to distinguish between the solder balls from the top and bottom parts.

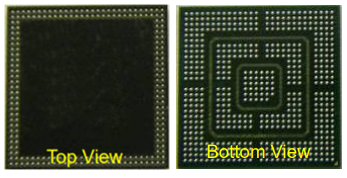

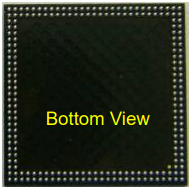

The images below show a standard POP-style part, to give an idea of how some pads on the bottom chip might be covered. For this sort of package, it is only the outer ring that might be blocked in the X-Ray image, since those are the only pads that overlap between the 2 packages

Processor

Memory

The issues in X-Ray inspection can be more fully solved using Two-Step Reflow, but this method does require more additional cost and lead time compared with the Single-Pass method. In Two-Step Reflow, the memory chips are placed on top of the processors first, and soldered independent of the boards. This allows for clear X-Ray Inspection of the interconnection between the two chips.

Bittele has generally not noticed any issues in using Single-Pass Reflow, which produces good results for POP assembly. We also offer many Quality Assurance options to ensure that your boards will function as intended, such as Functional Testing and our Turnkey PCB Sample Program. Clients who would like the additional X-Ray Inspection data for even more confidence can request Two-Step Reflow during the quote phase of the project.

For more information about Bittele or our POP Assembly capabilities, please contact us any time! We can be reached via email at sales@7pcb.com, or toll free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English