TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Bittele's PCB handling and Storage

Handling

Assembled PCBs need a high degree of caution and care when working with them to safely transport them without any damage. Below are a few examples of our packaging techniques that are designed to ensure your package gets delivered safely and properly.

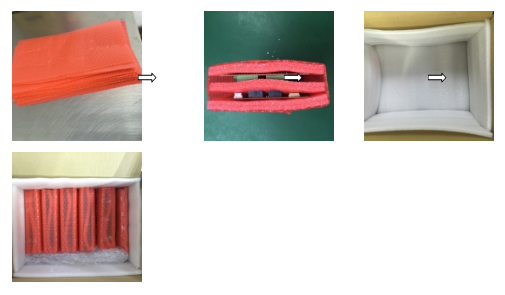

The red buffer foam and the red bubble film are used to safely and tightly pack the boards in the box. We follow very strict packaging guidelines to ensure the boards arrive safely and without any damage. Below is an example of how we would package the boards.

ESD Damage

one of the leading causes for malfunctioning/damaged PCBs is ESD damage. ESD damage is the result of contact between two electrically charged surfaces. Here at Bittele, we take numerous steps to ensure that none of the boards encounter any type of damage during shipping.

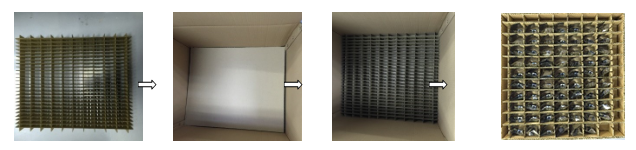

For ESD sensitive boards, we send them out in ESD bags and package them as below.

Humidity and Temperature

Surface mounts components (SMTs), are able to absorb moisture which could potentially cause unforeseen damage. When the moisture absorbed SMTs go through soldering, the rise of heat causes the moisture vapours to expand and causes delamination of the internal package interfaces.

To prevent moisture damage, humidity indicator cards are used to ensure the room’s humidity is less than 75%. Also, The PCBs should not be stored in an acidic or alkaline environment. Additionally, the storage temperature should be less than 30°C.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English