TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Bittele's PCB Aspect Ratio Capabilities

When a board is designed there are a few capabilities to keep in mind, such as the minimum trace width and space and the minimum via size. Another capability that should be kept in mind is called the PCB Aspect Ratio.

The PCB Aspect Ratio is defined as the ratio of the thickness of a PCB compared to the diameter of the smallest hole drilled in the same PCB. The thickness of the PCB is the thickness without copper plating, solder, or solder mask. The larger this aspect ratio is the more difficult the plating process will be.

As the aspect ratio increases more plating will be required and thus there is a proportional increase in the risk of cracking due to expansion during the assembly process. A lower aspect ratio will have the benefit of stronger vias that provide better electrical connections.

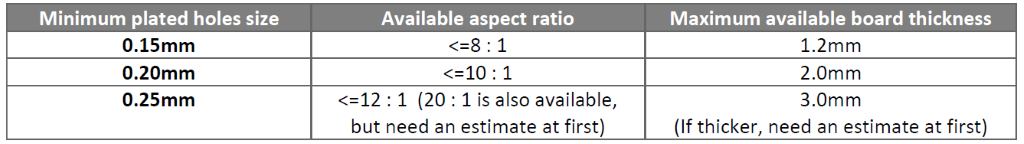

At Bittele Electronics our PCB Aspect Ratios can be seen in the below table:

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English