TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Bittele's Capabilities for Soldering Irregular Parts

PCB components come in many different shapes and sizes, and Bittele Electronics is happy to help with any type of component package your design requires. In addition to our support for PCB Assembly of standard parts, including passives down to 0201, QFN Assembly, and BGA Assembly, we are continually improving our PCB Assembly Process to support a variety of non-standard and irregular package types. This article examines a number of examples of irregular component packages from a PCB assembly perspective, providing advice for Bittele’s clients in Design for Assembly (DFA) with regard to these parts where applicable.

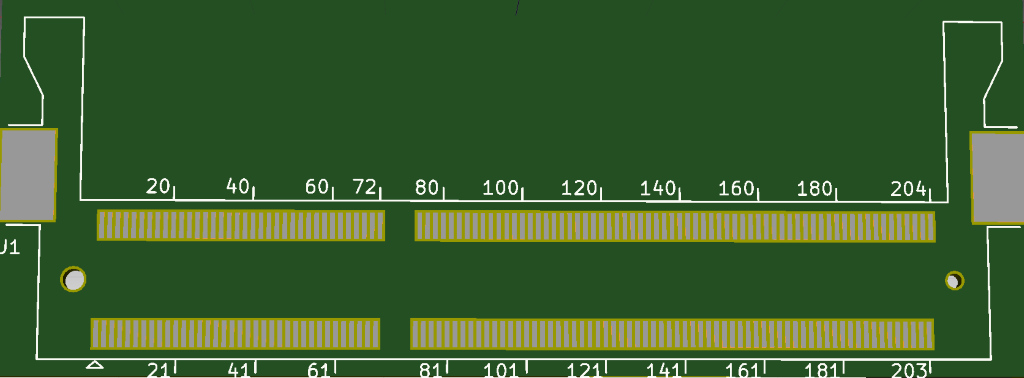

Connectors & Contacts

In addition to standard pin headers, some PCB designs require specialized connectors for interfacing with other PCBs or electronic devices. Bittele can support all standard connector types, such as UFL connectors, coaxial connectors, and IC sockets. We also commonly provide assembly services for custom connectors by manufacturers such as Samtec and Mill-Max. These types of connectors present no problem for us, so long as detailed datasheets are readily available for our production team.

Spring-loaded contacts (sometimes called spring fingers, shield fingers, grounding springs, or antenna clips) are also used quite frequently in RF and other high-speed applications to provide grounding or shielding. Placement of these components is crucial to design functionality, and Bittele is able to provide placement accuracy with ± 0.04 mm (1.6 mil) tolerance.

Press-Fit Parts

Press-Fit parts are not assembled using standard PCB Assembly practices, such as Reflow Soldering or Wave Soldering. Instead of soldering, press-fit parts are held in place by the plated holes themselves. Press-fit holes have very strict tolerance requirements, compared to standard plated holes for Through-Hole Assembly. Bittele is able to provide diameter tolerance up to ±2 mil for press-fit holes.

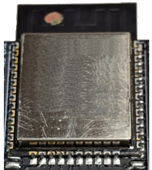

Modules

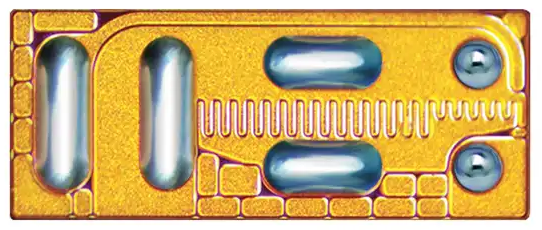

The term “module”, with regard to component package types, most often refers to application specific ICs (ASICs), complex microprocessors, and interfacing devices that come mounted on a very small, pre-assembled, mass-produced PCB. The term is particularly common in the realm of wireless RF devices. Modules are often mounted using Castellated Holes around the edge of the smaller PCB, but some are mounted using gold fingers or even simple through-hole connections, either of which might require dedicated connectors. Some PCB component manufacturers tend to use the term “module” as sort of a catch-all term for irregular package types.

Bittele can provide assembly for Module-type packages, as long as they fall within our regular capabilities according to our DFA Guidelines. These types of packages do not normally require any special attention during PCB Assembly, and they can be treated as standard surface mount parts. The module shown in the picture above would likely be treated similarly to a QFN package component.

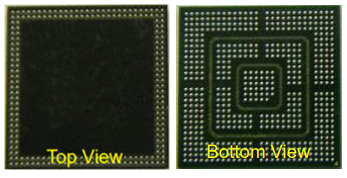

Part-On-Part (POP) Assembly

POP Assembly is an advanced PCB Assembly technology that allows for certain components to be assembled one atop the other. This strategy allows for considerable space optimization in High-Density Interconnect (HDI) designs and helps to minimize interference in communication lines for the stacked parts. These advantages can be absolutely crucial for specialized applications involving high-speed processors, but the advantages must be weighed carefully against the necessary complications of POP technology in PCB Assembly.

Bittele can provide POP Assembly when necessary, but our standard assembly process must be adapted to suit multiple instances of paste screening and reflow soldering, which can be especially tedious for high-volume orders. If your project requires POP Assembly, you should get in touch with one of our PCB Customer Service Experts early in the development cycle for DFA advice.

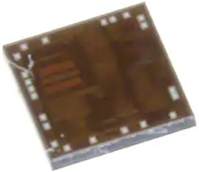

Problem Packages

Though we are continuously improving our capabilities, there are still some package types that should be avoided when you choose Bittele for your PCB Assembly needs.

Bittele is currently working on support for assembly of semiconductor die packages, as seen in the images below. These fragile package types leave the semiconductor die exposed, without the regular protective coating that is seen on common package types such as SOIC, QFP, QFN, or BGA packages. The exposed die presents challenges during PCB assembly, including handling concerns and heat dissipation during the reflow soldering process.

Other package types that are currently under development include DSBGA (Die Size Ball Grid Array), Flip Chip, and 01005 size passive parts.

If you have a question about any package type note mentioned in this article, please feel free to Contact Us any time! We are always happy to work with you to find an appropriate solution and get your PCBs assembled with the utmost in quality and care.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English