TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

J-STD-001 and IPC-A-610 Standards in PCB Industry

Electronics assemblies with high quality and reliability are essential to the efficiency, safety and performance of electronic devices in the manufacturing industry. The J-STD-001 and IPC-A-610 standards are commonly recognized around the electronics manufacturing industry as benchmarks for ensuring high-quality and reliable PCB assemblies. Association Connecting Electronics Industries (IPC) published these guidelines for the PCB assembly and manufacturing industry to serve as foundational guidelines for soldering processes, workmanship, inspection, and product acceptability specifically in applications where safety and performance are crucial.

J-STD-001, identified as "Requirements for Soldered Electrical and Electronic Assemblies," concentrate on the materials, methods, and process controls require to produce high-reliability soldered assemblies.

Key Areas Covered:

- Materials and Equipment Requirements: Specifies types of solders (lead-free, tin-lead), flux, cleaning agents, and handling tools. Ensures compatibility and reliability of materials used in different environments.

- Process Requirements: Establishes criteria for acceptable soldering methods, including hand soldering, wave soldering, and reflow soldering, with a strong emphasis on process control to ensure consistency and minimize defects.

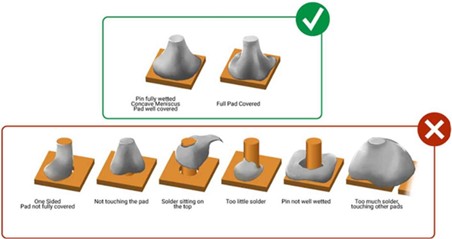

- Soldering Criteria: Covers through-hole, surface mount, and terminal connections. Highlighting the importance of joint integrity, proper wetting, fillet shape and solder quality.

- Workmanship Standards: Provides clear guidelines for clean, well-aligned, and properly terminated assemblies. Addresses mechanical damage, contamination, and handling precautions.

- Training and Certification: Requires that personnel be properly trained and certified to ensures they are competent, proficient and that production quality is consistently maintained.

- Inspection and Acceptance Testing: Specifies in-process and final inspection protocols. Integrates with IPC-A-610 for visual inspection standards.

- Classes of Product Ǫuality: Make sure that all soldering and assembly procedures adhere to the required standards of quality and reliability, in accordance with the specific demands of the intended end- use application.

Classes of Products:

Class 1: General Electronic Devices (e.g., computer peripherals)

Class 2: Dedicated Electronic Devices (e.g., commercial equipment)

Class 3: High Reliability Electronic Devices (e.g., military, medical)

On the other hand, IPC-A-610, known as "Acceptability of Electronic Assemblies," visually defines the acceptability guideline of electronic assemblies including solder joints, component placement, and cleanliness. It complements J-STD-001 by providing illustrated guidelines for inspection.

Key Areas Covered:

- Solder Joint Acceptability: Provides high-resolution images showing what is considered acceptable, process- indicative, or a defect for solder joints.

- Component Mounting and Placement: Details correct orientation, alignment, and positioning of components on PCBs. Covers SMT, through-hole, and mixed technology.

- Board and Component Damage Criteria: Summarize evident signs of defects like cracks, chipping, delamination, and solder bridging.

- Lead Forming and Terminations: Defines acceptable lead bends, cuts, and connections for axial, radial, and gull-wing leads.

- Surface Cleanliness and Contamination: Specifies criteria for board cleanliness, flux residue, foreign materials, and corrosion risks.

- Coatings and Markings: Define standardized criteria for conformal coating application, including acceptable thickness ranges, coverage areas, and the clarity of labeling and marking.

Classification of Defects

Differentiates between:

Acceptable: Meets all criteria

Process Indicator: Minor deviation, not affecting function

Defect: Not acceptable, affect performance, quality

The combined use of J-STD-001 and IPC-A-610 brings numerous benefits to PCB assembly. First, these improve product reliability by ensuring robust and consistent soldering practices. Standardized quality benchmarks across production lines make it easier to meet customer expectations and regulatory requirements, particularly in industries such as user electronic products, automotive, telecommunications, and medical devices. These criteria also enhance quality assurance and inspection processes by providing clear standard for evaluating assemblies, thereby reducing subjectivity and improving defect detection accuracy. In addition, these support continuous improvement by promoting better process control, reducing rework and scrap, and enabling root-cause analysis. The requirement for certified operators and inspectors further reinforces production reliability and helps reduce human error. Finally, the use of these standards improves communication between design, production, and quality teams, enabling smoother audits, better documentation, and more effective problem resolution.

For more information about our capabilities or to send us your PCB Design Files for an official quotation, please feel free to Contact Us any time! We can be reached via email at sales@7pcb.com or call at 1-416-800-7540.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English