TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

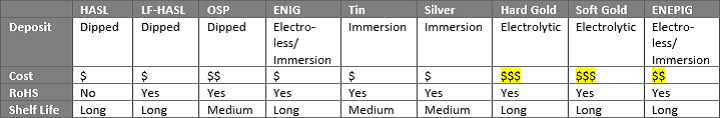

Full Body and Selective PCB Hard Gold Plating

The Hard Gold surface finish, also known as Hard Electrolytic Gold, is composed of a layer of gold with added hardeners for increased durability, plated over a barrier coat of nickel using an electrolytic process. Hard gold is extremely durable, so during PCB Fabrication this finish is usually applied to high-wear areas, such as edge connector Gold Fingers and keypads, since the hardness of the finish can withstand repeated use; however, due to the high cost of hard gold, and its relatively poor solder-ability, it is very rarely applied to solder-able areas.

Full Body Hard Gold is generally a rarely-chosen surface finish, where the full body of the PCB board is plated with hard gold. In order to apply a Full Body Hard Gold surface finish, an electrolytic process using an electric current or an immersion process is needed, depending on the PCB design. For Complete PCB Assembly projects, where we fabricate and assemble the boards, we will also need to consider the poor solderability of this finish; a very active flux will be required to solder effectively to the hard-gold-plated pad.

Pros

|

Cons

|

|---|

At Bittele, we offer a few options for gold surface finishes to which we can adapt our PCB Assembly Process, providing our clients with the utmost flexibility while still supporting our meticulous PCB Quality Management standards.

Selective Gold involves using a hard gold surface finish to plate specific areas on a PCB. Please note that for quotation purposes, “Gold Fingers” are treated as a separate entity, so you do not need to ask for a Selective Gold surface finish just to cover those edge connectors. The application process for Selective Gold is nearly the same as Full Body Hard Gold, but the Selective method does require some masking that will accrue additional labour charges, balanced out by decreased material cost.

At Bittele, we offer both Full-Body and Selective PCB Hard Gold surface finishes, but please note that the associated cost of these methods depend largely upon the specific amount of gold that will be required. To maximize efficiency, please send an Assembly Drawing ahead of your main PCB Design Files so that we can collaborate with our production team and develop a plan.

If you have any further questions about our PCB Surface Finish capabilities, or to get started on your project with Bittele today, you can Contact Us over email at sales@7pcb.com, or toll-free at 1-888-812-1949. Bittele Electronics is a Canadian PCB Assembly service provider, based out of Toronto, but serving clients worldwide since 2003.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English