TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Flexible Copper Clad Laminated

Structure of Three-Layer Flexible Copper Clad Laminates

In the early 1970s, the U.S. PCB industry was the first to industrialize flexible printed circuit (FPCs) technology, which were initially used primarily in military electronics. This innovation introduced a new category of PCB products globally. The core substrate material used was emerged alongside this development is the Flexible Copper Clad Laminate (FCCL). Traditional FCCL is composed of three distinct functional layers. (a) Metal conductor foil typically copper served as the conductive layer, (b) Insulating film served as the dielectric base, and (c) Adhesive used in three-layer FCCLs to bond the conductor foil to the insulating film. This structure is commonly referred to as a "three-layer FCCL."

Most adhesives composition used today are modified epoxy resins, followed by acrylicbased adhesives. In terms of conductor foils, FCCLs can be manufactured using standard electrolytic copper foil, high-ductility electrolytic copper, rolled annealed (RA) copper foil, copper-beryllium alloy foil, and other alloyed RA copper foils or aluminum. Among these, RA copper foil remains the most widely used. And for the insulating films, the majority of FCCLs use polyimide (PI) films as the dielectric base, with polyester (PET) films are used in smaller volumes. The use of other insulation base films is relatively small.

Each of the three primary materials contributes differently to FCCL performance. Copper foil influences the mechanical flexibility and signal integrity of the FCCL in which essential for both high-density and high-speed signal transmission. Adhesives affect thermal resistance (high Tg) and bonding strength and play a key role in achieving halogenfree FCCLs by modifying flame-retardant components. While insulating films influence on moisture resistance (low moisture absorption rate), mechanical strength, dimensional stability, chemical resistance, and thickness accuracy of FCCLs.

Differences Between Two-Layer and Three-Layer FCCLs

In recent years, adhesive-free FCCLs has gained widespread adoption, especially for miniaturized and high-performance FPC applications. This has led to FCCLs used in FPCs to classify into two main types based on structure.

- Three-layer FCCL which contains adhesive, often referred to as "adhesive-based" FCCL (traditional structure).

- Two-layer FCCL with no adhesive between the copper and base film referred to as "adhesiveless" FCCL.

Although two-layer FCCLs are often defined as "adhesiveless", this is technically not accurate. In manufacturing processes such as coating or lamination, a thin layer of thermoplastic polyimide resin is often applied between the copper and base film to enhance the bonding. Technically, this resin layer still acts as an adhesive.

Two-layer FCCLs offer several advantages over three-layer types. Two-layer has superior chemical resistance, enhanced flexibility, and improve thermal resistance. It also has enhanced peel strength at high temperatures, supports thinner constructions and easier implementation of halogen-free designs. As a result, two-layer FCCLs are increasingly used in high-density interconnect FPCs such as COF (Chip on Film), TAB (Tape Automated Bonding), Flexible CSP substrates, and Rigid-flex PCBs.

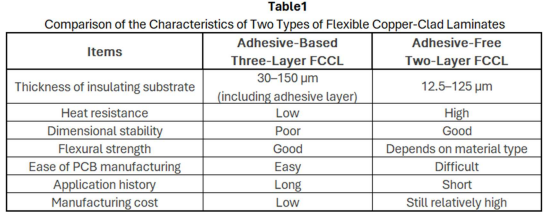

Table1 gives a comparison of the characteristics and applications of the two types of flexible copper clad laminates.

As summary, “Three-layer FCCL corresponds to what is commonly referred to as adhesivebased materials; two-layer FCCL corresponds to adhesive-free materials.”

Our sales team will be more than happy to assist you as well as provide you with information on pricing and/or lead-time regarding your PCB/PCBA. To make an inquiry, please send your PCB Design Files and any special requirements to sales@7pcb.com.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English