TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

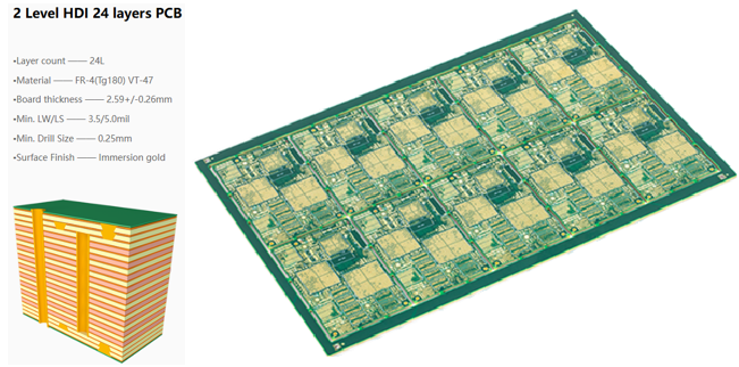

HDI PCB - Circuit Board Manufacturing

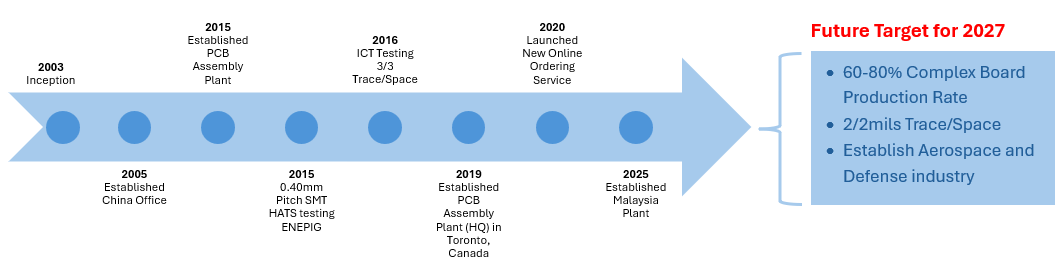

In 2016, Bittele Electronics improved its manufacturing facilities by adding High Density Interconnect(HDI) PCB manufacturing to our comprehensive capabilities in PCB Fabrication and PCB Assembly. We are happy to offer Complete PCB Assembly services for HDI PCB projects.

HDI PCBs are printed circuit boards with a much higher wiring and pad connection density than a traditional PCB. HDI PCBs are characterized by finer lines, closer spaces, smaller capture pads, and Micro-Vias. HDI PCB manufacturing is a growing area since market demand for lightweight and thinner PCBs that can handle High Speed Signals with low signal loss has steadily increased as consumer electronics end-products are produced in smaller form factors.

As a result of the market demand for HDI PCB manufacturing, Bittele Electronics has served clients from many industries, including:

- Automotive (Engine Control Units, GPS, Dashboard Electronics)

- Computers (Laptops, Tablets, Wearable Electronics, Internet of Things - IoT)

- Communication (Mobile phones, Modules, Routers, Switches)

- Digitial (Cameras, Audio, Video)

Our manufacturing facilities have the following HDI PCB manufacturing capabilities:

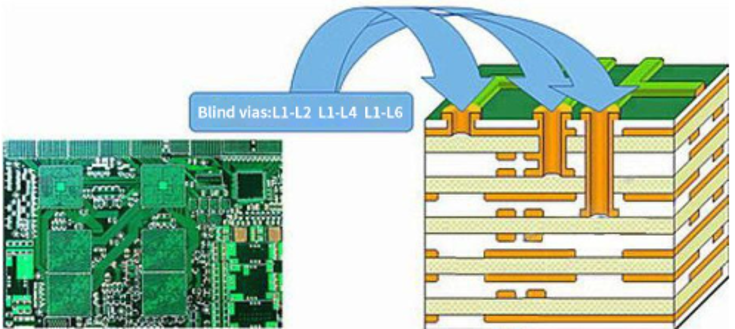

- Micro Vias, including Buried and Blind Vias

- Non-Conductive Via-Filling (NCVF)

- Copper Fill

- Sequential Lamination

- 3/3mils Traces/Space

- 5% Controlled Impedance tolerance

At the present time, Bittele Electronics can produce sequential lamination boards of up to 40 layers. Our facilities have been fitted with the most advanced Laser Drilling Machines, which are capable of laser drilling holes as small as 2mils [0.05mm]. With the latest HDI technology, we can produce inner and outer layers with as little as a 3/3mils Trace/Space featuring excellent registration. We also have very large inventory of raw PCB Materials, including North American & exotic materials.

Please refer to the technology roadmap below to see the full list of our HDI capabilities.

| Bittele HDI Technology Matrix | |

|---|---|

| Laser Drill | 2mils [0.05mm] Min. |

| Copper Pad | 6mils [0.15mm] bigger than via hole size |

| Micro Via | 6mils [0.15mm] Max. |

| Smallest BGA | 16mils [0.40mm] |

| Trace/Space | 3/3 mils [0.075/0.075mm] |

| Impedance | ±5% (for 50Ω) ±10% (for > 50Ω) |

Bittele Electronics is committed to continuously improving and refining our HDI PCB manufacturing services. In 2027, our target goal is to produce more complex board that occupy our production capacity up to 80%. Establish the business in both aerospace and defense customers. And build PCB board with 2/2mils tracewidth/space.

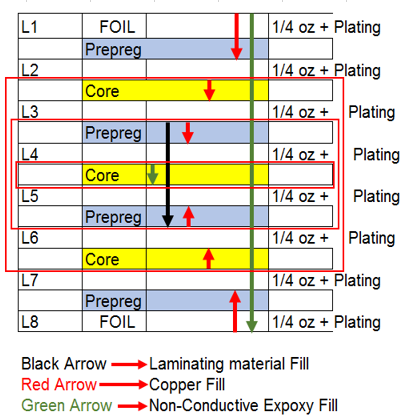

The picture below illustrates the type of HDI we specialize in. We carry 1/4 oz and 3/8 oz Foils for your HDI needs. We are also capable of performing back drilling, controlled depth drilling, and Press Fit holes (tight hole tolerance). Bittele has ability to use cores (laminates) as thin as 1mil. We also offer Buried Capacitance (BC) Cores. Other technologies include dual FINISH, multiple color Solder Mask & silk screen, Gold Fingers, hybrid builds, etc.

For more detailed information on the HDI technologies we use in our manufacturing facilities, or for any questions about our PCB Assembly Process in general, please feel free to Contact Us any time.

English

English