TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

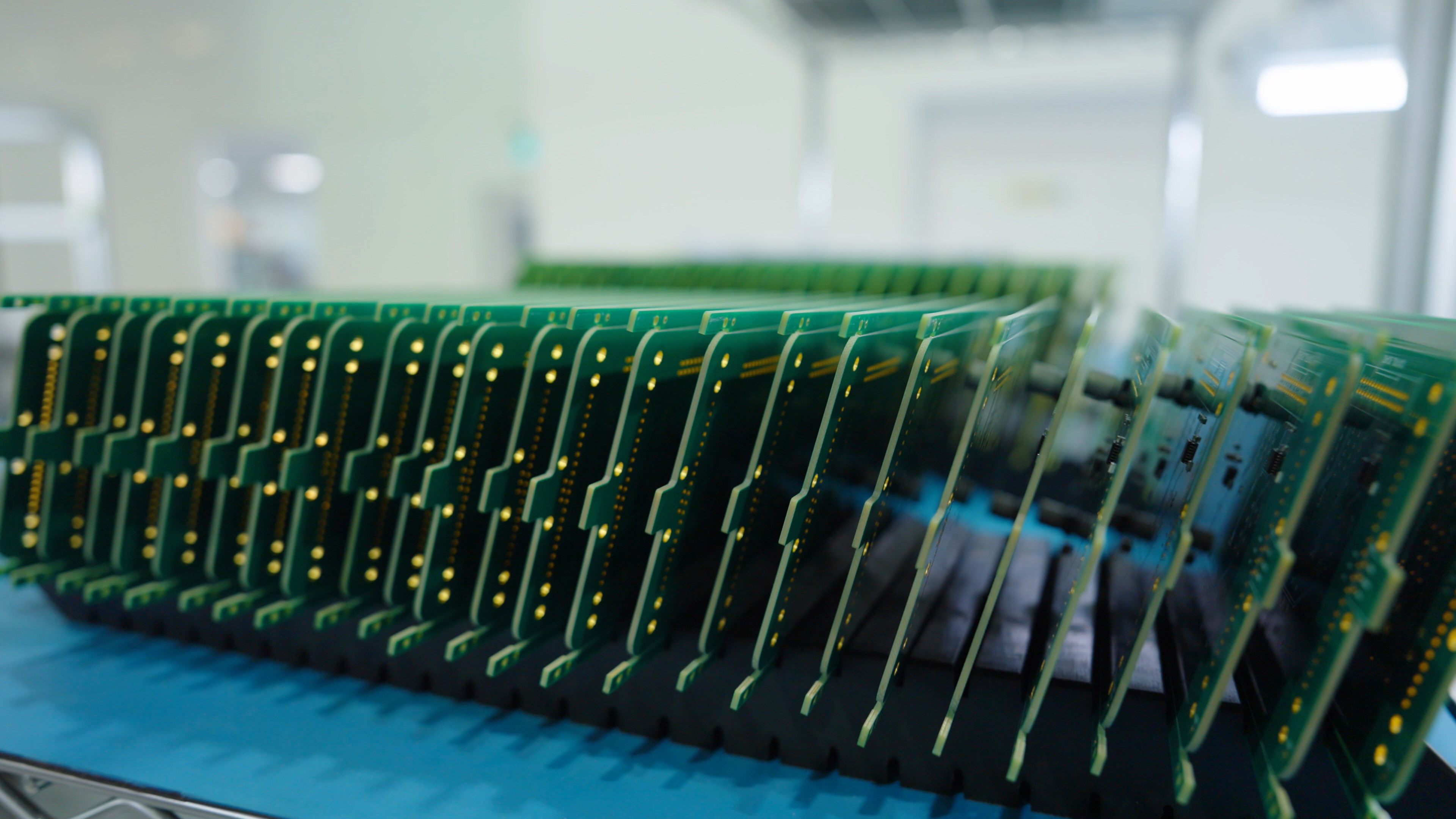

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

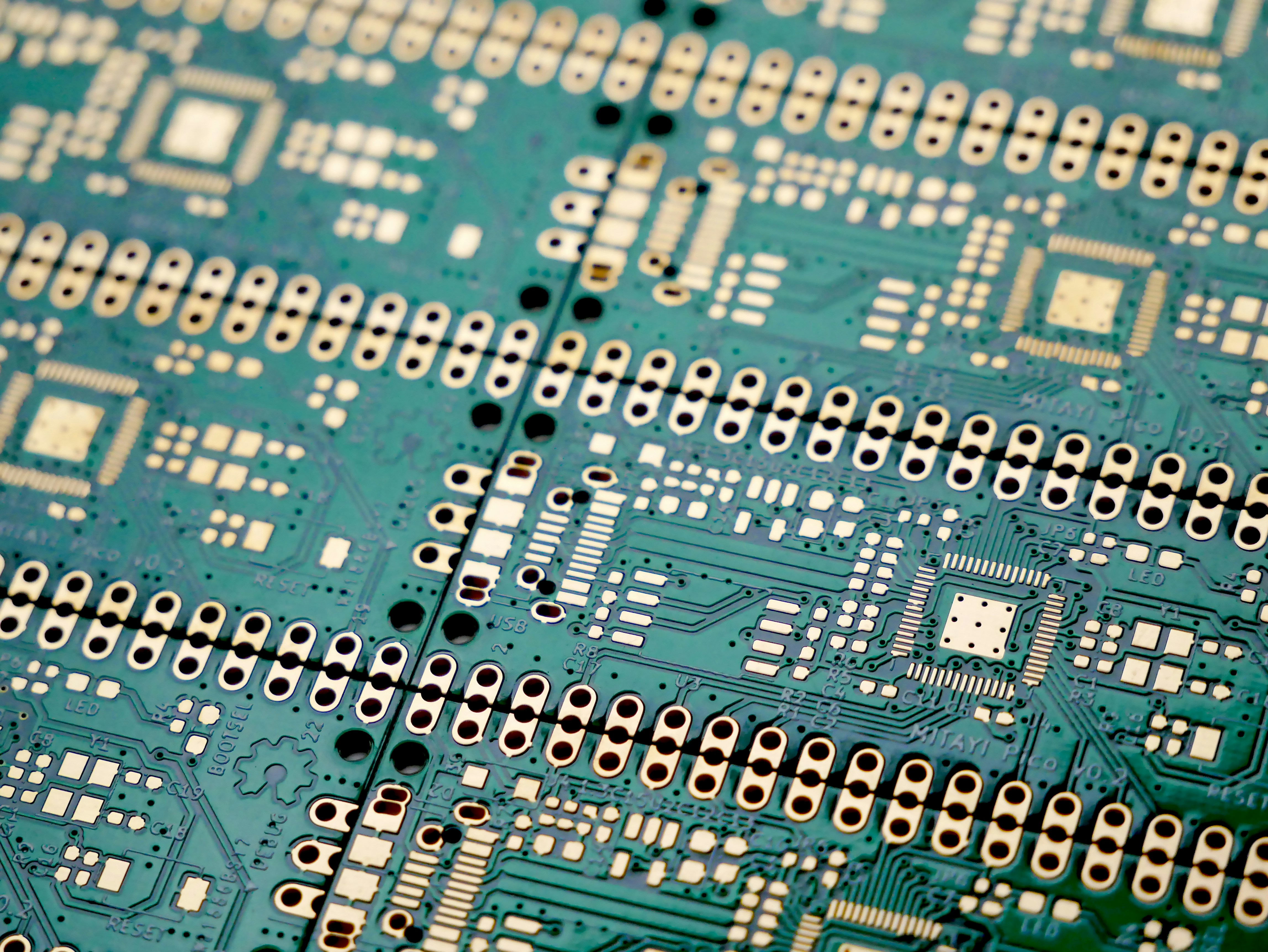

Why are most PCB circuit boards green?

You may be curious about why most printed circuit boards (PCBs) are green. In fact, this phenomenon has profound historical reasons and technical considerations. This article will take you to explore and reveal why PCBs prefer green.

First, let's take a look at the development of PCBs. Early PCBs were mainly made using cloth boards , so they did not have a uniform color, but depended on the materials used. However, in the late 1960s, advances in printing technology promoted the use of fiberglass -based PCBs. At the same time, due to the development of printed circuit materials and structures, green became the main choice because of its many advantages.

To better understand why green is the dominant color, we need to understand the composition of PCBs. A PCB is usually composed of multiple layers of circuit boards, each of which is connected by interlayer interconnects. The green color is actually caused by the insulating layer coated on the surface of the PCB . The insulating layer is mainly composed of glass fiber and resin, and a pigment called solder mask green ink is added during its manufacturing process . This green liquid has good insulating properties, which can effectively isolate the circuit layers and provide good electrical performance.

In addition to its insulating properties, green solder mask ink also offers other advantages. First, it can prevent metal corrosion and oxidation on the surface of the PCB, ensuring the long life and stability of the circuit board. Second, green can provide higher contrast during PCB manufacturing, making it easier to check solder joints and circuit connections, helping to reduce errors in the manufacturing process. In addition, green can also provide a certain amount of heat reflection during the soldering process, making the soldering spot more clearly visible. These advantages make green solder mask ink the first choice for manufacturers and engineers.

In addition, green has become the iconic color of PCB to a certain extent. When many people see green PCB in electronic devices, they will immediately associate it with electronic devices and their advanced functions. Therefore, even if the technology allows, manufacturers tend to use green PCB to meet market demand and customer preferences.

Of course, although green is the mainstream choice, it does not mean that other colors cannot be used. In some specific projects, manufacturers and designers can choose other colors of PCB according to specific needs, such as red, blue, black, etc. The choice of these colors may be affected by specific industries or design styles.

In summary, there are historical reasons and technical considerations for green to become the dominant color of PCB. Solder mask green ink not only has good insulation and oxidation protection capabilities, but also provides advantages such as contrast and heat reflection, making it the first choice for manufacturers and engineers. In addition, green PCBs also meet market demand and customer preferences. Although green is the mainstream choice, other colors of PCBs can also be selected under specific needs.

I hope this article can answer your questions about why PCBs are mostly green. If you have other questions about PCBs or electronic devices, please continue to leave a message. Thank you for reading!

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English