TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

What core roles does BOM play in SMT manufacturing?

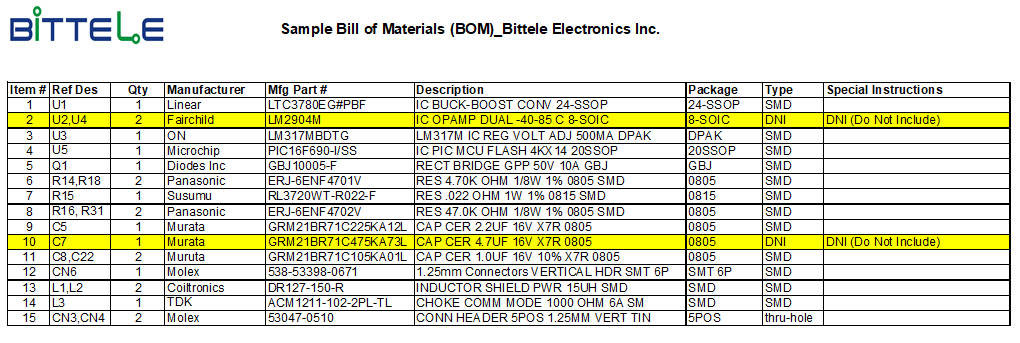

When we talk about electronic manufacturing, especially SMT (Surface Mount Technology), the importance of BOM (Bill of Materials) cannot be ignored.

BOM is not only a simple component list, but also plays a vital role in the entire process of SMT. So, what are the specific functions of SMT BOM?

Clear material requirements and procurement basis

The primary function of a BOM is to list in detail all the raw materials, components, assemblies, and subassemblies required to manufacture a product. For an SMT production line, this means that every resistor, capacitor, IC, and other electronic component has clear specifications and quantity requirements. This provides the procurement team with an accurate list to ensure that they can purchase the required materials in a timely and accurate manner according to production requirements.

Cost Control and Budgeting

Through BOM, enterprises can accurately calculate the material cost of products. When compared with supplier quotations, enterprises can clearly understand the price fluctuations of each component, so as to carry out cost control and budget adjustment in a targeted manner.

Production Planning and Scheduling

On an SMT production line, time is money. Any production delays can lead to higher costs and lower customer satisfaction. BOM provides a clear roadmap for production planning teams to understand the specific material requirements for upcoming production tasks. This helps optimize material flow, reduce production line downtime, and ensure that production runs smoothly as planned.

Quality Control and Traceability

Quality control is critical in electronics manufacturing. Each component listed in the BOM is associated with a specific supplier, batch, and date. When product quality issues occur, this information provides the quality team with the ability to quickly trace and locate the source of the problem, so that corrective measures can be taken in a timely manner.

Documentation and communication tools

BOM is not just an internal tool. It is also a key document for communicating with external partners, suppliers and customers. A complete and accurate BOM can ensure that all relevant parties have a clear and consistent understanding of the material requirements of the product, thus avoiding misunderstandings and communication barriers.

Engineering Change and Version Control

Engineering changes are inevitable during the life cycle of electronic products. Whether it is to optimize performance, reduce costs or meet new market requirements, BOM provides a structured framework for engineering teams to manage and track these changes. With version control, companies can ensure that at any given point in time, there is an accurate and up-to-date bill of materials for reference.

SMT's BOM plays a core role in the entire electronic manufacturing process. From procurement to production, to quality control and communication, BOM is the key to ensuring a smooth and efficient process. For any company engaged in SMT business, optimizing and improving BOM management is an important way to improve competitiveness, reduce risks and increase profits.

If you have any SMT assembly needs, please feel free to contact us at Bittele Electronics. We will wholeheartedly provide you with professional support and solutions.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English