TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

What Are the Standard Electrical Properties for Bittele's PCB Materials

Bittele Electronics uses a variety of different materials to serve your printed circuit board needs. The purpose of these materials is to provide the necessary insulation between the conducting copper layers and obviously conduct the electricity. The most commonly used PCB material is the FR-4, however, Bittele offers a variety of other materials that can be used to serve your boards specific needs. The chart below will show our most commonly used materials and this article will provide a bit more information regarding them to help you with your selection.

| Material Type | Material we have in stock |

|---|---|

| FR4 TG140 | S1000H, IT158 |

| FR4 TG170 | S1000-2, IT180A, TU768 |

| Rogers material | Ro4350B, Ro4003, Ro3003 |

| Polymide material | SH260 |

| Flex material | SF202 |

| Coverlay | SF305 |

The first material we use under this type is the S1000H. Some general features of this material are:

- Lead-free compatible

- Excellent thermal reliability

- Low Z-axis CTE

- Good in anti-CAF performance and IST

- Low water absorption

- Computer and NB

- Instruments

- Consumer electronics

- Automotive electronics

- Power supplier and industrial

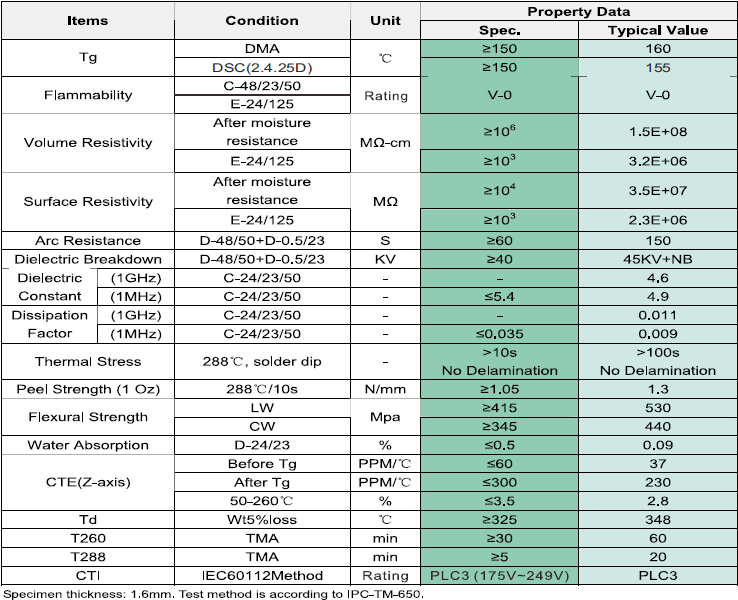

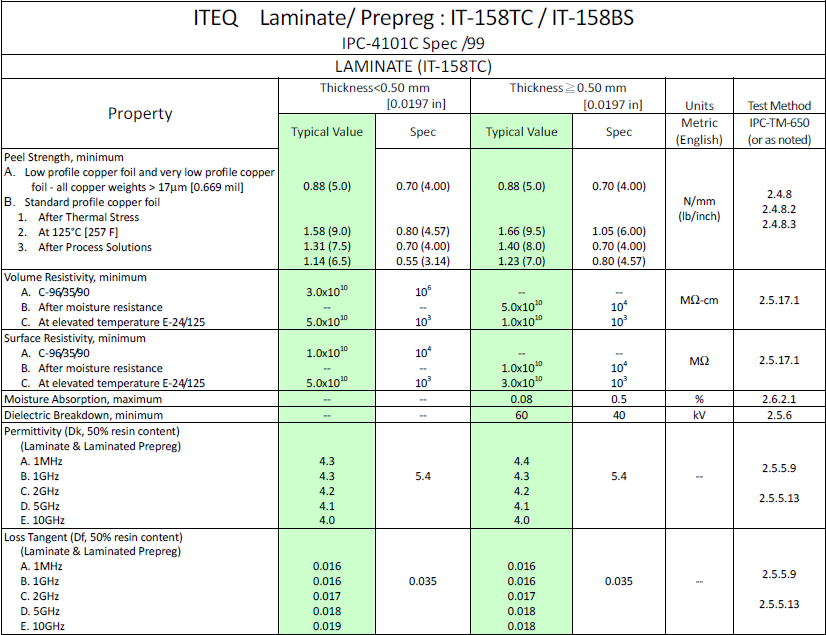

Another material we use under this type is the IT158. Some general features of this material are:

- Lead-free assembly compatible

- Advanced resin technology

- Friendly processing and CAF resistance

- CAF resistance

- Available in a variety of Constructions

One material we use under this type is the S1000-2. Some general features of this material are:

- Lead-free compatible FR-4 laminate

- Tg 170°C (DSC), UV Blocking / AOI compatible

- High heat resistance

- Lower Z-axis CTE

- Excellent through-hole reliability

- Excellent anti-CAF performance

- Lower water absorption

- Suitable for high aspect ratio and high-layer PCB

- Widely used in computer, communication equipment, precise apparatus and instrument, routers, etc.

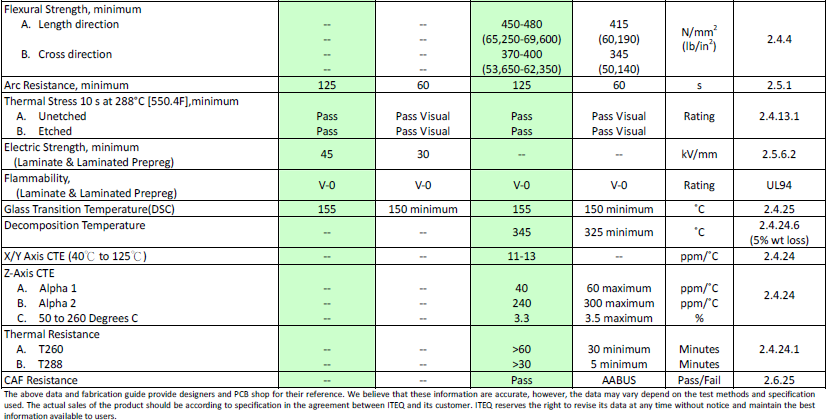

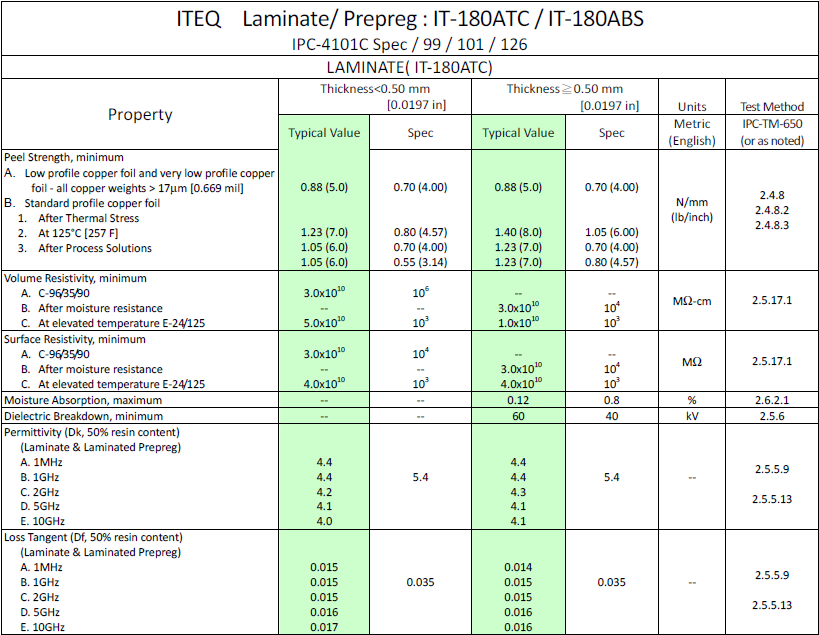

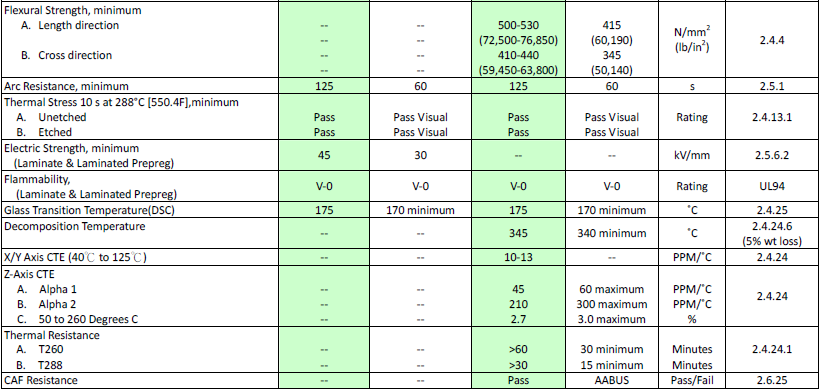

Another material we use under this type is the IT1A80A. Some general features of this material are:

- Advanced High Tg Resin Technology

- Lead-Free Assembly Compatible

- Friendly Processing and CAF Resistance

- CAF Resistance

- Available in Variety of Constructions

- Multilayer and High Layer PCB

- Automobile

- Backplanes

- Servers and Networking

- Telecommunications

- Data Storage

- Heavy Copper Application

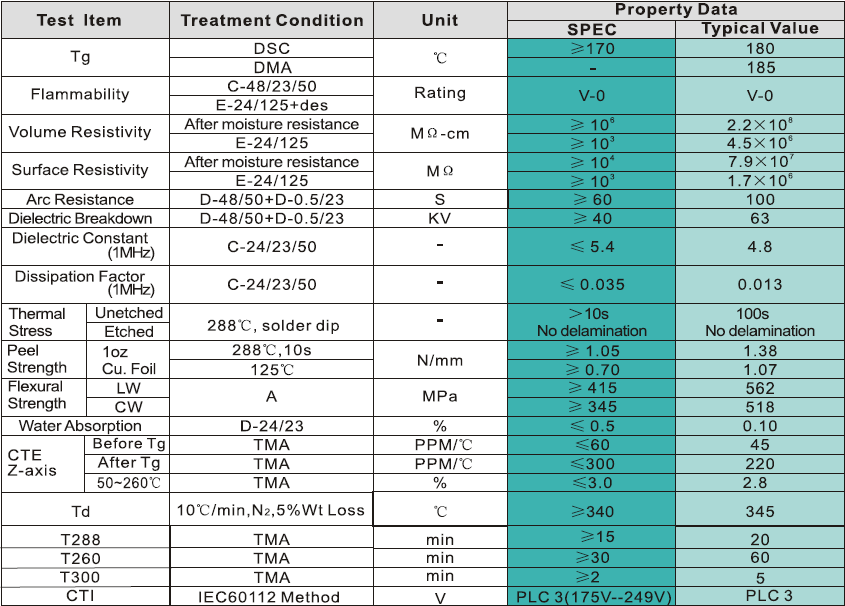

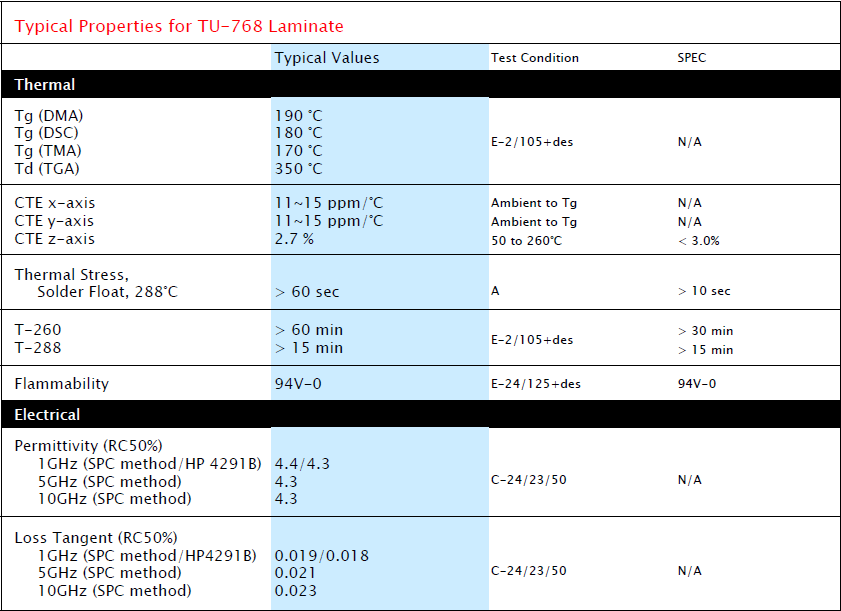

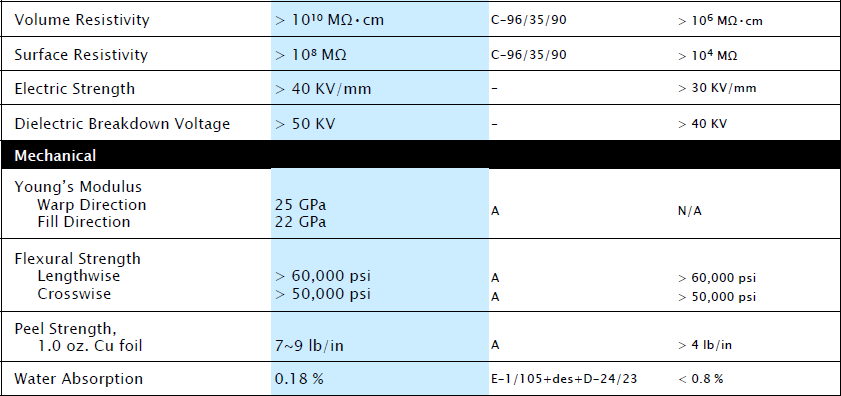

Another material we use under this type is the TU768. Some general features of this material are:

- Lead Free process compatible

- Excellent coefficient of thermal expansion

- Anti-CAF property

- Superior chemical and thermal resistance

- Fluorescence for AOI

- Moisture resistance

- Consumer Electronics

- Server, workstation

- Automotive

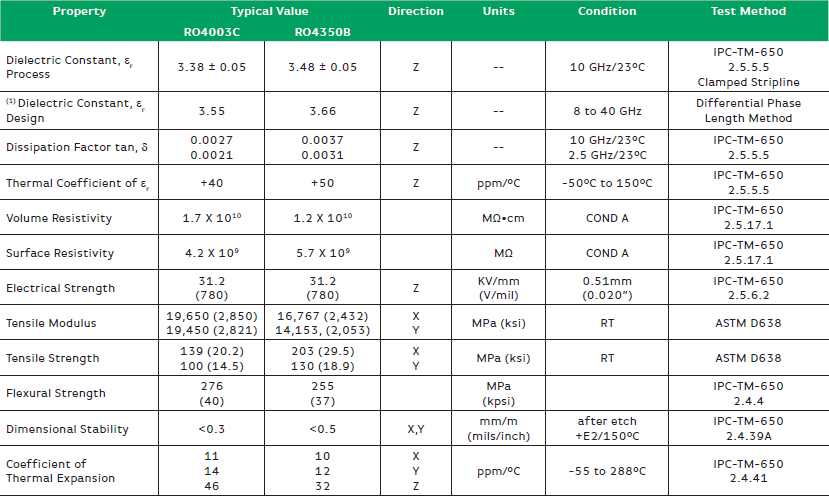

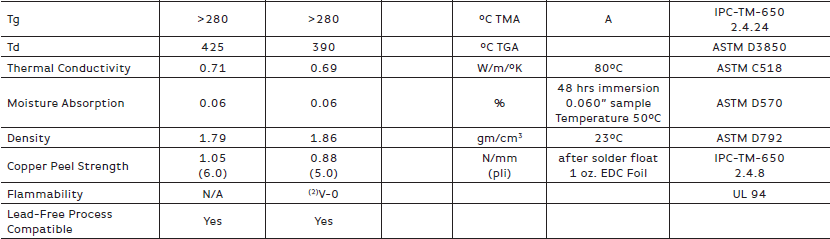

Two materials we use under this type are the Ro4003 and Ro4350B. Some general features of these material are:

- RO4000 materials are reinforced hydrocarbon/ceramic laminates – not PTFE

- Low dielectric tolerance and low loss

- Stable electrical properties vs. frequency

- Low thermal coefficient of dielectric constant

- Low Z-axis expansion

- Low in-plane expansion coefficient

- Volume manufacturing process

- CAF resistant

- Cellular Base Station Antennas and Power Amplifiers

- RF Identification Tags

- Automotive Radar and Sensors

- LNB’s for Direct Broadcast Satellites

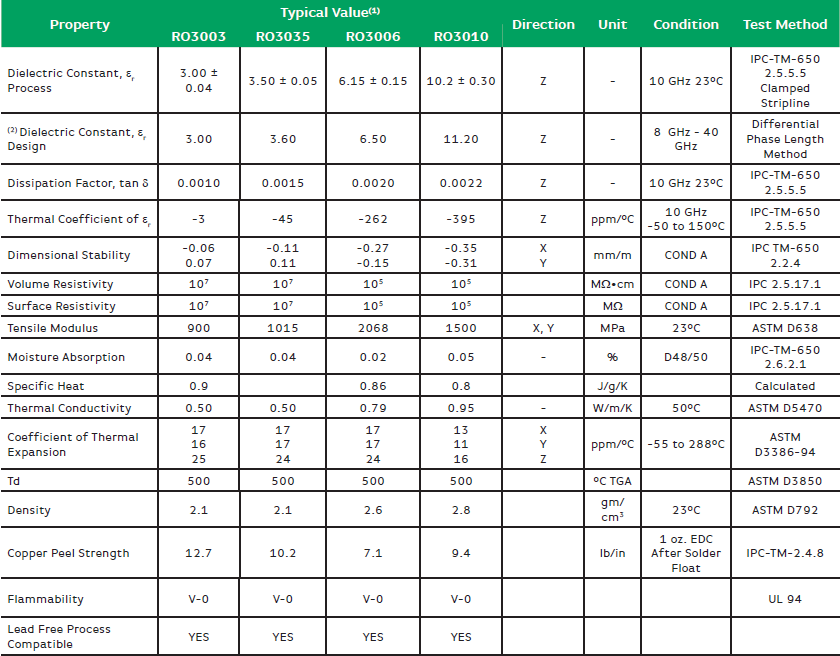

Another material we use under this type is the Ro3003. Some general features of this material are:

- Low dielectric loss (RO3003™ laminates)

- Excellent mechanical properties versus temperature

- Uniform mechanical properties for a range of dielectric constants

- Stable dielectric constant versus temperature and frequency (RO3003 laminates)

- Low in-plane expansion coefficient (match to copper)

- Volume manufacturing process

- Automotive radar applications

- Global positioning satellite antennas

- Cellular telecommunications systems - power amplifiers and antennas

- Patch antenna for wireless communications

- Direct broadcast satellites

- Datalink on cable systems

- Remote meter readers

- Power backplanes

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English