TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Slots and Cutouts in PCB Fabrication and PCB Assembly

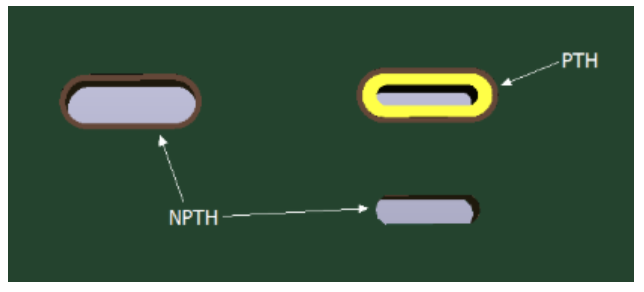

In addition to the relatively small holes required for Through Hole PCB Assembly and the mounting holes located on a board, many PCBs also specify Slots and Cutouts, also known as Internal Routing. These names are used to refer to holes in the PCB that are too large or irregularly shaped to be created by normal drilling methods, and must instead be cut out with a routing bit during PCB Fabrication. Internal routing holes can be either plated or non-plated, as per the client’s request, since these holes are sometimes used to connect the board to other PCBs, or to the chassis of a device.

At Bittele Electronics, we sometimes receive questions from clients who wonder whether the presence of slots or cutouts in their PCB will act to increase the price or lead time of their project. Thanks to the flexible and comprehensive nature of our PCB Assembly Process, we are able to assure these clients that their slots and cutouts will cost them no more than a regular drill hole in the PCB.

The only additional thing to keep in mind when specifying internal routing on your PCB is that, while not particularly uncommon, these types of holes are not exactly standard either. As such, it would be beneficial to call attention to these features in a mechanical layer of your Gerber Files, and perhaps in your initial email to Bittele, along with your PCB Design Files.

For detailed information regarding the design of internal routing, please see our comprehensive guide on Best Practices for Plated Slots, which also covers non-plated internal routing practices.

You can also Contact Us with any further questions. Feel free to reach out over email at sales@7pcb.com any time, or call us toll-free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English