TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Rectangular PCBs – Manufacturing & Assembly

Printed Circuit Boards come in many different shapes and sizes, and Bittele is able to provide High Quality PCB Assembly for any type of PCB, but the most common shape by far has always been a simple rectangular design. The consistency of the rectangular PCB’s popularity is no coincidence either. Of course, many device enclosures are themselves rectangular, so rectangular PCBs are a natural fit in these instances, but there are also advantages to a simple rectangular shape that relate to the PCB Assembly Process. This article outlines the various benefits of a rectangular PCB design in order to help our clients reach a more informed decision on the shape of their upcoming PCB projects.

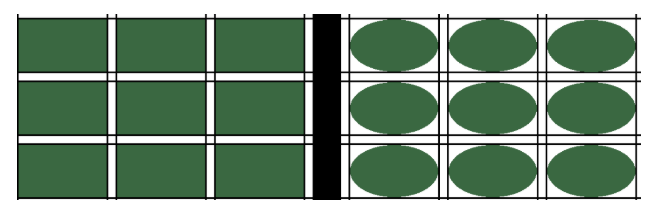

First of all, it should be noted that PCB Panelization is an important step in our Turnkey PCB Assembly service. From Prototype PCB Assembly orders to Volume PCB Production runs, panelization is a key strategy for maximizing the efficiency of our procedures. If you consider a large panel of PCB Material, housing many different boards, it should be quite clear that a rectangular PCB shape will minimize the amount of empty space on the panel. Rectangular boards can be easily tiled onto the panel with only a minimal gap, where other shapes such as Round PCBs will necessitate larger areas of empty space simply due to their geometry. The image below shows a very simple example of this fact.

It is clear from the image above that the panel of round PCBs leaves more empty space on the panel. The Length by Width dimensions are identical for the PCBs on both the left and right panel, but the rectangular shape allows for maximum surface area usage within those dimensions.

When our PCB Customer Service Experts are developing your official PCB Fabrication Quote, the dimensions of your board will be taken into account, but unlike some other PCB service providers, we will not apply any additional cost or Turnaround Time for the shape of your boards. Ultimately, the rectangular and round boards shown above would come out to be the same price, but the rectangular format would allow a PCB layout designer more space to route traces and place components.

We do hope that this article has answered any questions you might have about the reasoning behind rectangular PCBs, but please feel free to get in touch with our team if you find yourself with any further questions! You can Contact Us any time via email at sales@7pcb.com, or you can reach us over the phone at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English