TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

PTFE Teflon PCBs

PTFE (Polytetrafluoroethylene) is the scientific name for a very well-known product, even outside the engineering community; DuPont’s trademarked Teflon has applications extending far beyond your kitchen, and into many high-speed electronic devices across a variety of industries. At Bittele Electronics, we are proud to offer a wide variety of PCB Laminate Materials for our clients’ convenience, including multiple varieties of PTFE laminates from Rogers. This article is intended to provide Bittele’s clients with basic information regarding these High-Frequency PCB Materials, as well as their effects on the PCB Assembly Process, in order to facilitate a more informed decision making process where PCB materials are concerned.

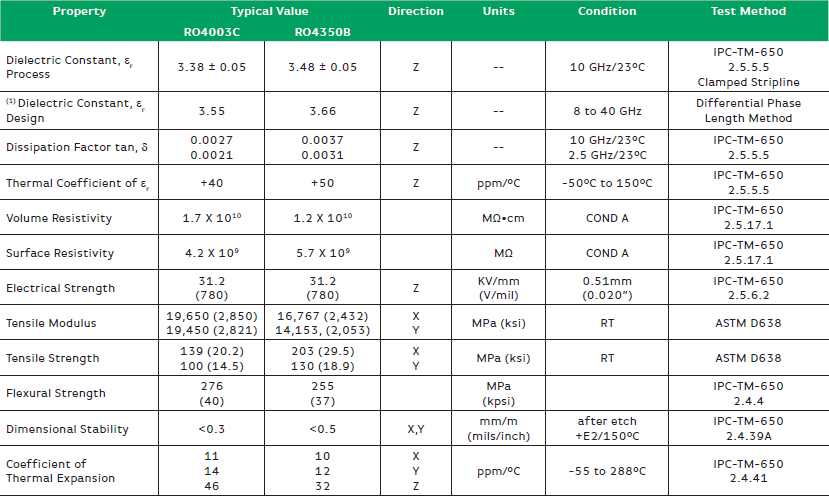

As mentioned briefly above, PTFE materials are valued for their suitability in high-frequency applications. At RF and Microwave frequencies, the dielectric constant of standard FR-4 Material (approx. 4.5) is often too high, resulting in significant signal loss during transmission across the PCB. Fortunately, PTFE materials boast dielectric constant values as low as 3.5 or below, making them ideal for overcoming the high-speed limitations of FR-4. The most common of these PTFE PCB materials were developed by Rogers, and are denoted by an “RO” prefix in their product name. In addition to a reduction in dielectric constant, these materials also offer very impressive thermal characteristics for High Temperature PCB applications, reaching Tg values as high as 280°C. A datasheet comparison is shown below for two different PTFE materials, RO4003C and RO4350B.

Of course, every product has its benefits and its drawbacks, and PTFE material is no exception to this rule. Perhaps most importantly, PTFE material, unlike FR-4, is not included among Bittele’s PCB Options at a Standard Price, and the cost of this material is significantly greater than standard FR-4.

PTFE materials also require additional care during PCB Fabrication due to a few specific aspects of the material itself, relative to standard FR-4. First of all, PTFE materials are rather soft, making them prone to gouging or tearing while PCB Routing and PCB Drilling operations are performed. The other main concern during production relates to PTFE’s most well-known aspect: this material is used to coat frying pans and cookpots because of the slick, non-stick surface it provides. Unfortunately, this same property can make it difficult to produce Plated Through-Holes and Slots, since the copper plating requires specialized techniques to seed the PTFE with metal for bonding. These complications also contribute to the higher cost of PCB Fabrication for PTFE materials.

Since PTFE is only necessary for specialized applications, we do not always carry stock for all different types of common PTFE laminates. Be sure to check in with our PCB Customer Service Experts well in advance of your order to ensure that we can provide the material you require.

PTFE is an incredibly useful material for PCB Fabrication and PCB Assembly, but its advantages must be weighed carefully against its costs in order to maximize the economy of your PCB project. If you need any help in these assessments, Bittele Electronics is happy to be of assistance in any way we can. You can Contact Us for advice any time at sales@7pcb.com, or toll-free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English