TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Proper Component Alignment for PCB Assembly

In this age of miniaturization and HDI PCBs, the effort to get the most out of the space on your board can often overshadow the importance of proper component alignment, but keeping this aspect of your design in mind can lead to a significant increase in the efficiency of the PCB Assembly Process. This article is intended to remind Bittele’s clients about rules for proper component alignment, and to explain how this aspect of the design can facilitate a Fast Turnaround Time for your High Quality PCB Assembly project. It is important to note that the rules presented in this article are not by any means absolute. We understand that the nature of a given design sometimes necessitates deviation from ideal alignment guidelines, but simply keeping this information in mind can have a significant effect during production.

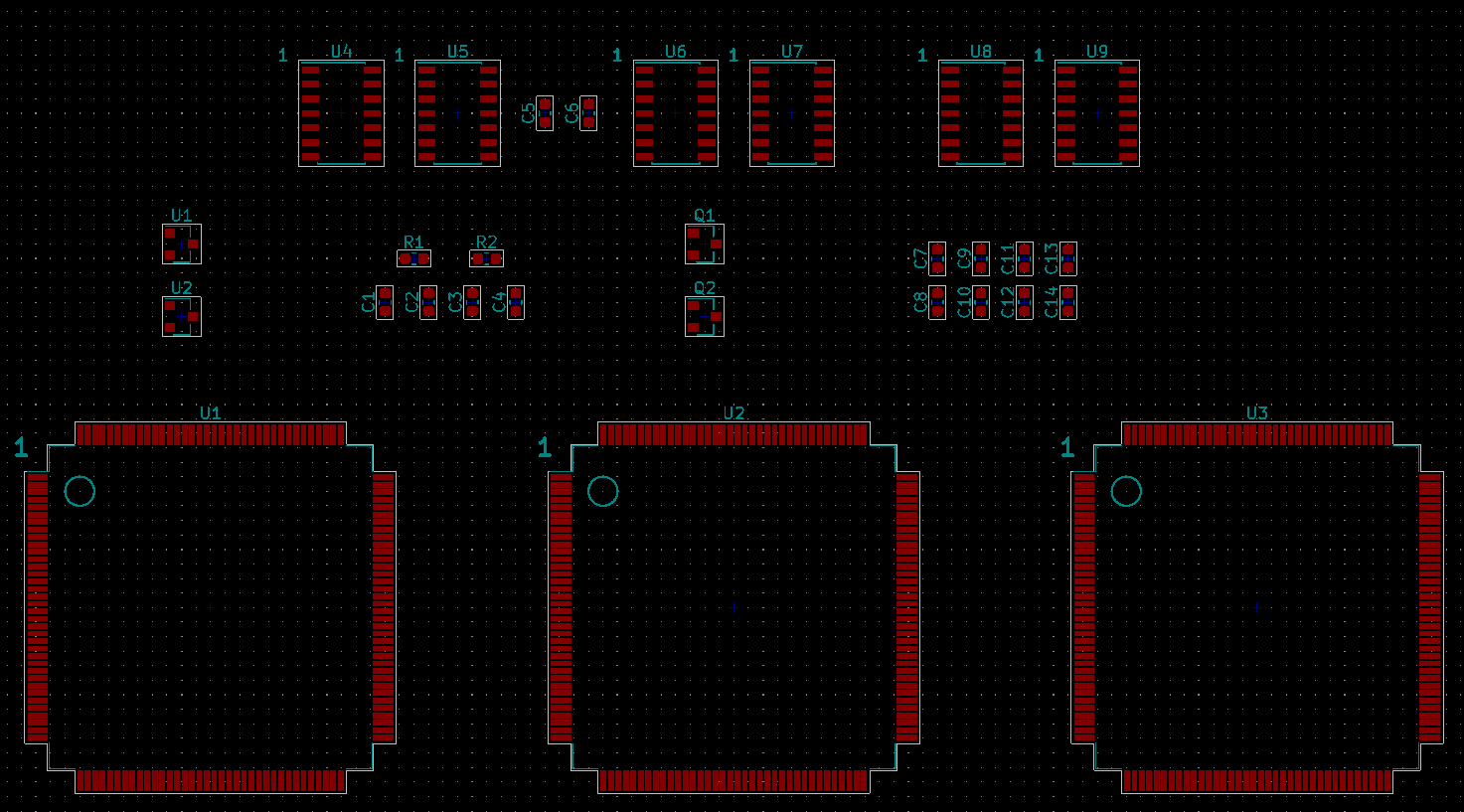

Quite simply, the ideal for component alignment is to group together similar or identical Component Packages, and to specify the same orientation for each of these, throughout the grouping, as shown in the picture below. For example: all QFP packages are placed in a row, with Pin 1 at the top left-hand corner for each IC.

This alignment procedure allows for a more efficient Automated Assembly Process via Pick & Place machines, and the same benefits are observed in Solder Mask application. If the actuator does not have to spend much time moving between areas on the PCB, the process takes place more quickly, and the lead time for your project is effectively reduced. This becomes particularly important for larger orders such as Mid-Volume Production runs. Even small groups of similar components yields considerable advantage in this respect, compared to a design with similar components scattered across the PCB.

Proper alignment also has benefits in the testing and inspection stages of a project. Bittele provides many advanced testing methods, including AOI (Automated Optical Inspection), X-Ray Inspection, ICT (In-Circuit Testing), and FCT (Functional Circuit Testing), but Visual Inspection is still an important aspect of verification since it can be performed quickly in between each stage of production. Our Quality Management team is extremely adept at catching Common PCB Assembly Faults as soon as they appear, but proper alignment can help to make these checks even more reliable.

If you still find yourself with any questions about proper alignment, or to send in the PCB Design Files for your PCB project today, please feel free to Contact Us any time! You can reach us over email at sales@7pcb.com, or call us toll-free at 1-888-812-1949.

Bittele is a full-service provider of low-cost Canada-Based PCB Assembly solutions. In business since 2003, we have established ourselves as a leader in the PCB production industry, and we offer a variety of tailored solutions to meet your specific needs.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English