TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

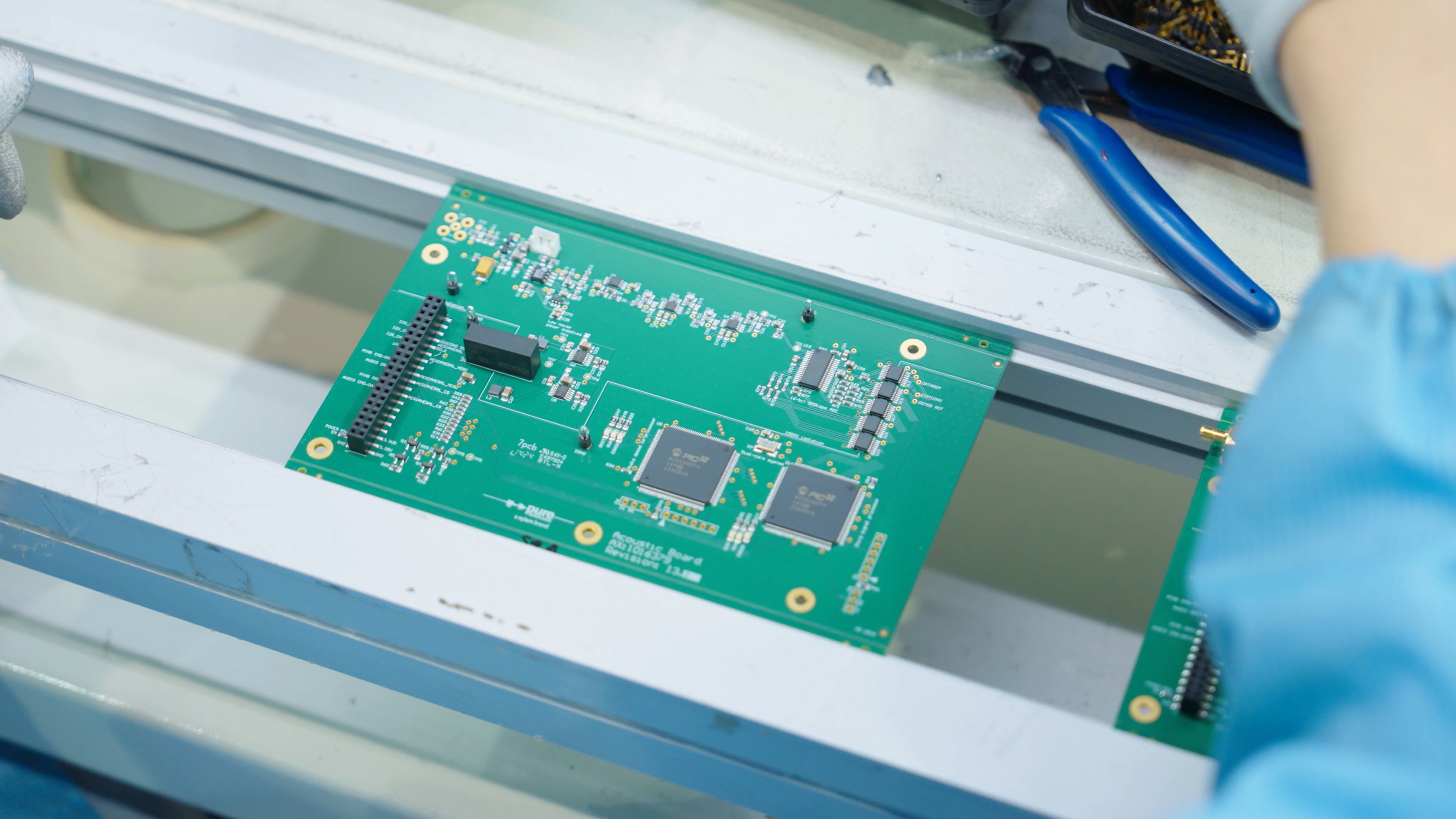

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

PCBA panel proofing: importance and advantages

With the continuous development and innovation of the electronic product market, PCBA panel proofing, as an important technical process, has been paid more and more attention by manufacturers and engineers. This article will analyze in detail the importance of PCBA panel proofing and its advantages.

01. PCBA panel proofing plays a vital role in product development.

In the early stages of product innovation, designers and engineers often need to test and verify their designs and concepts. PCBA panel proofing provides a feasible way to achieve this goal. Through proofing, they can quickly obtain physical samples and conduct rigorous testing and evaluation on them. This can discover and solve problems in early designs and improve product quality and performance.

02. PCBA panel prototyping helps reduce development costs and time.

In the process of product development, various problems and challenges will inevitably arise. Without prototyping, designers and engineers need to go directly into mass production and may face higher risks. Through prototyping, they can solve problems in advance before mass production and reduce R&D costs and time during the development process.

03. PCBA panelization proofing also helps improve product stability and reliability.

Proofing can help designers and engineers evaluate and optimize key aspects such as circuit board layout, connection and welding. Through repeated testing and modification, they can find the best solution to improve product stability and reliability. This is essential to ensure the normal operation of the product in various environments.

04. It is worth mentioning that PCBA panel proofing can also effectively reduce production risks.

Before mass production, the feasibility and reliability of the circuit board can be verified and tested through proofing. Designers and engineers can make improvements based on the problems found during the proofing process, thereby reducing the quality problems and failure rates that may occur in the mass production stage. This can not only improve user satisfaction and brand reputation, but also save maintenance and after-sales costs.

In summary, the importance of PCBA panelization in the development and production of electronic products cannot be ignored. It can help designers and engineers find and solve problems early, reduce development costs and time, and improve product quality and stability. Therefore, manufacturers and engineers should pay full attention to PCBA panelization in the process of product innovation, and actively take effective measures to ensure its smooth progress.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English