TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

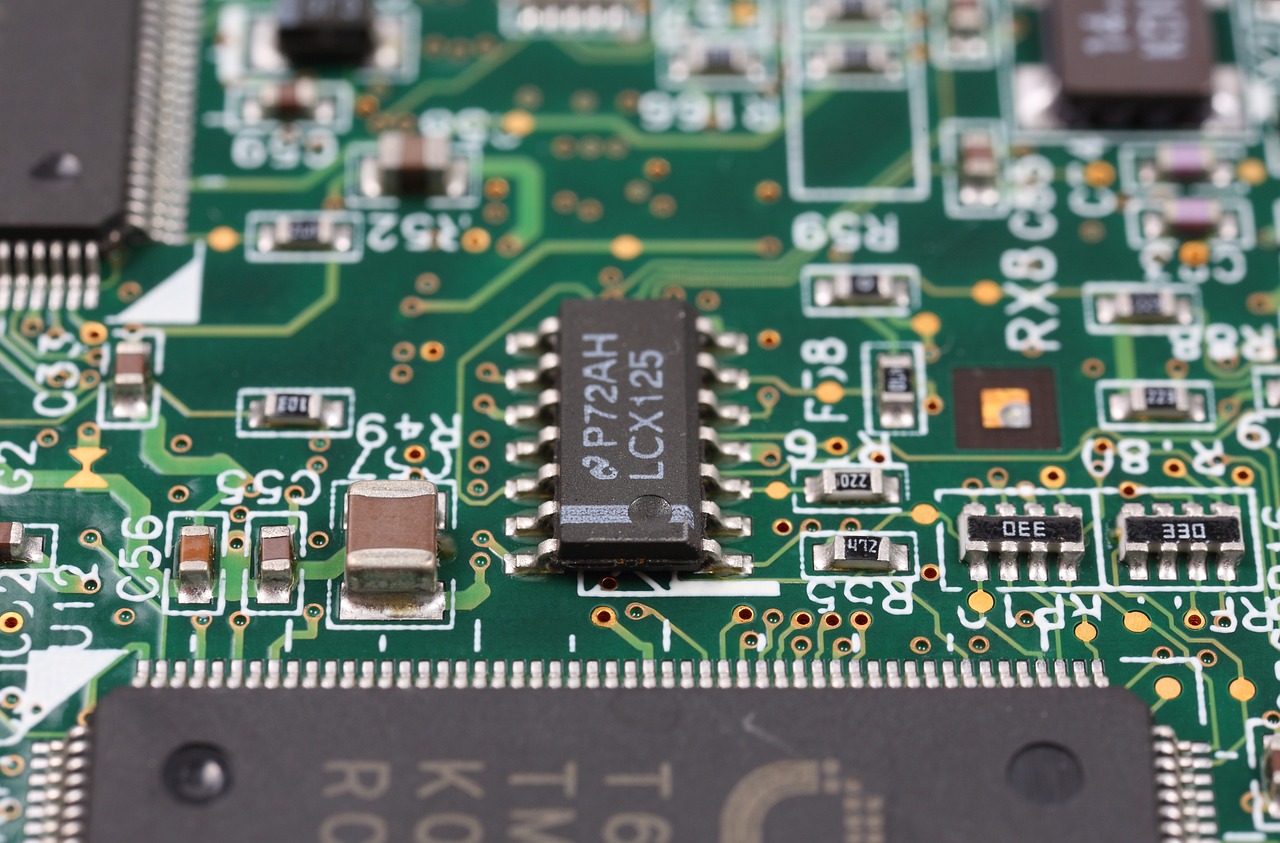

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Detailed explanation of PCB selective soldering

In the field of electronic manufacturing, welding is an indispensable link. With the continuous development of technology, traditional welding methods are gradually replaced by more advanced selective welding technology. This article will analyze in detail the principles, advantages and applications of PCB selective welding technology.

Principles of Selective Soldering Technology

Selective soldering technology is a method of soldering specific areas or components on a PCB. It precisely controls the heat source of the soldering equipment so that the soldering process only heats the target area, thereby avoiding affecting other parts. Selective soldering technology usually uses high-precision heat sources such as lasers and infrared to achieve precise control of the soldering area.

Advantages of Selective Soldering Technology

- High precision: Selective welding technology has high positioning accuracy and welding accuracy, which can ensure welding quality.

- Flexibility: This technology can be used to weld components of different shapes, sizes and materials, and has high adaptability.

- Environmental protection: Since selective welding technology uses local heating, the heat affected zone is smaller, which is beneficial to reduce energy consumption and environmental pollution.

- Improve production efficiency: Through precise welding control, the rework rate caused by problems such as mis-welding and leaking welding can be reduced, thereby improving production efficiency.

Application of Selective Soldering Technology

- Soldering of micro-pitch components: With the continuous miniaturization of electronic components, soldering of micro-pitch components has become a challenge. Selective soldering technology can achieve high-precision soldering of micro-pitch components by precisely controlling the heat source.

- Welding of dissimilar materials: In the PCB manufacturing process, it is often necessary to weld components of different materials together. Selective welding technology can adjust the heat source parameters according to the characteristics of different materials to achieve reliable connection between dissimilar materials.

- Welding of components with special shapes: For components with special shapes, such as round and special shapes, traditional welding methods often make it difficult to achieve high-quality connections. Selective welding technology can meet the welding needs of various components with special shapes by precisely controlling the shape and size of the heat source.

- Complex PCB board welding: With the continuous increase in the functions of electronic products, the complexity of PCB boards is also increasing. Selective soldering technology can achieve high-precision and high-efficiency welding on complex PCB boards to meet the manufacturing needs of complex electronic products.

- Rework and repair: In the PCB production process, poor welding or damage may occasionally occur. Selective soldering technology can be used to rework and repair these defective products to improve product yield.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English