TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

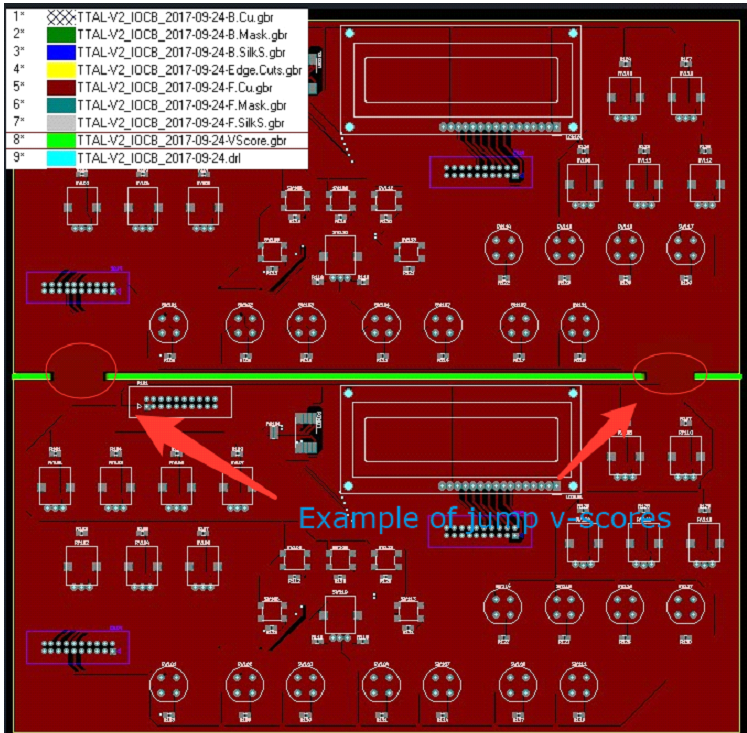

Jump V-Scoring Panelization

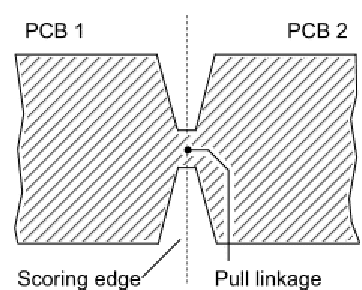

A "jump score" or "jump V-score/V-groove" is a specific type of V-scoring used in panelized PCB design and fabrication. Similar to a standard V-Score panelization, a jump score etches a "V" shaped groove along a straight line marked on the PCB surface. The depth of this cut is controlled so that a third of the PCB thickness is removed from the top and another third from the bottom, leaving a thin layer of material that keeps the boards connected but allows them to be separated after assembly.

While a standard V-score typically runs continuously along the entire marked line on the board, a jump V-score features segmented cuts, creating a discontinuous line. This segmented approach provides additional stability and flexibility in certain manufacturing and assembly processes, enhancing control over the separation process. This becomes important when a board is large or includes heavy components close to the edges of the board, as a standard V-score may cause issues during assembly, such as causing an uneven sagging of the board, leading to improper soldering in reflow soldering machines. A jump V-score allows the boards to be scored while maintaining rigidity under these conditions.

Incorporating jump V-scoring into your design also minimizes material waste and increases the efficiency of rails. The segmented cuts from jump V-scoring allow for precise scoring in necessary areas while leaving more of the PCB intact, thereby reducing waste and optimizing the use of rails.

As jump V-scoring requires precise control and added complexity, an account manager must manually quote this special requirement. If this is a requirement you have, please feel free to contact us and send your Gerber files (RS274X format) to sales@7pcb.com or call us toll-free at 1-888-812-1949. We will respond within one business day.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English