TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

How to get real-time thermal data for a PCB?

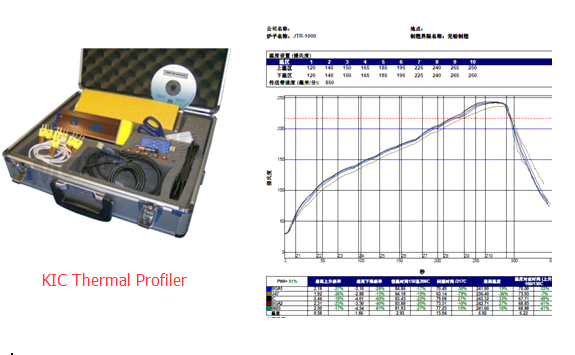

Although there is a thermal data testing function for our reflow oven, Bittele Electronics still uses a high-end, off-line, KIC thermal profiler as our key instrument for optimizing the reflow profile for every board.

These are the benefits of using an off-line thermal profiler:

- The off-line profiler uses standard type K thermocouple connectors. It goes through the oven with target board. So, you don’t need to prepare long wires to connect each thermocouple.

- It provides better data acquisition to precisely identify what is going on with each thermal profile and process in the production line.

- Thermal profile data are conveniently transferred to a computer via a USB connection. So, a process engineer can analyze and check the data for solder joint quality easily.

- Data Intelligence software such as Navigator Power is able to identify the best oven setup in seconds. A Process Window Index (PWI) is introduced to check if the profile is getting optimized -- the lower the PWI number, the more centered the profile is within the process window. A process engineer can use this result to manually adjust the profile easily.

Related Articles:

- Thermal Mass in PCBs and How Bittele Creates it’s Thermal Profiles

- Why does Bittele Use a 10 Zone Force air convection reflow oven?

- Under what conditions do you set different temperatures for the TOP and Bottom heating elements of a reflow oven?

- Reflow oven zone temperature set up and thermal profile

- How to attach a thermocouple to a target PCB?

Please briefly describe the information you are seeking in the search bar below.

English

English