TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Common Gerber File Issues, and How to Fix Them

Gerber files are an essential requirement for any PCB Fabrication or PCB Assembly project, including Bittele’s Complete PCB Assembly service. Of all the many types of PCB Design Files, Gerber files are perhaps the most important since they describe the physical attributes of your boards in a way that Bittele’s PCB fabrication machinery can directly process. Even for assembly-only projects, we still very much prefer to have the Gerber files on hand for the DFM Checking that we provide as a part of our comprehensive North American Quality Management standards.

Since PCB design is a complex process with many variables, it is of course not uncommon that some errors occur in a client’s Gerber files. Bittele’s team of PCB Customer Service Experts are extremely adept at catching these mistakes before production begins, but this can sometimes cause a delay in the PCB Assembly Process while clients correct the issues. As such, this article is intended to highlight some of the most common issues that we have noticed over our years of experience in dealing with Gerber files. We hope that this will allow our clients to develop a sort of checklist for their Gerbers, to ensure that they are correct and complete before submitting the project for quotation.

1 – Missing Board Outline

The board outline is perhaps the most simple and straightforward piece of your Gerber files, but it is still necessary to describe the actual bounds of the board edge to our fabrication machines so that the individual boards can be routed from the panel. When you generate your Gerber files, some CAD software packages will not produce a board outline by default, and must be specifically instructed to do so. The board outline can be described by its own Gerber file, or as a part of the general drill file(s), but it must be present somewhere, so make sure to double-check for it to save on communication time.

2 – Missing Excellon / NC Drill File

Similar to the first point, many PCB Design CAD software packages have a separate option for generating drill files and other Gerbers. This can make it easy to miss the drill file, which is required for creating any through-hole footprints that might be present in your design. We sometimes see a drill map submitted in place of the Excellon / NC Drill file, but the drill map contains only supplementary information that cannot be directly translated to our fabrication machines. Make sure to include drill files with the .xln or .drl extension for with your main Gerber file archive.

3 – Empty or Corrupted Gerber Data

Erroneous or empty Gerber data is usually very noticeable from a cursory look at the Gerber files, so it is highly recommended to use a Gerber Viewer to verify that your generated Gerbers match your design before submitting the package to Bittele. These issues normally result from incorrect settings within your CAD software, so check carefully that the Gerber generation is correctly specified. Bittele provides a number of convenient guides for correctly generating Gerber files in Eagle, KiCAD, Altium Designer, and AutoCAD.

4 – Incorrect File Format

The industry standard Gerber format is RS-274X, and this is the format required for Bittele’s PCB Fabrication process; we can also accept ODB++ Design Files for PCB Fabrication. We sometimes see clients who export to older formats, or who send their designs in using the file format of their specific CAD software, such as .brd for Eagle. Before you make your submission, we recommend that you double-check that your Gerbers are in the correct format.

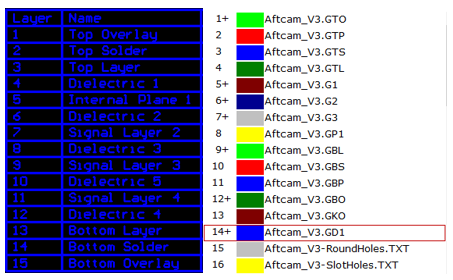

5 – Ambiguous File Names

For Multilayer PCBs and HDI PCBs, the order of the copper layers is often unclear from the file names themselves, so we highly recommend providing a simple PCB Stackup to make this information as clear as possible. The stackup can be included in your Fabrication Drawing, as its own PDF or Excel file, or directly within a mechanical layer of your Gerber files.

6 – Mis-Match with Other Design Files

We understand that the PCB design process occurs in multiple stages, and by the time you are ready to submit your design files to Bittele your design has likely gone through multiple revisions. Unfortunately, this might make it easy to overlook a revision on one of your design files, and the resulting discrepancies can cause confusion and potential delay during production. Before you submit your designs, it is a good idea to double-check that revisions have been reflected on your Gerber files, your Bill of Materials (BOM), your Centroid file, and any Fabrication or Assembly drawings you might choose to provide.

7 – Composite Layers

Some CAD software packages have a tendency to split 1 copper layer into many Gerber files. This phenomenon is most common for layers with filled areas, where the software will generate one file for copper pour, one for traces, and one for clearances. The issue results from a specific option within your CAD layout software, so make sure to double-check your files with a Gerber Viewer before submission, and correct your CAD software settings if necessary.

8 – Vectorized Pads

Vectorized pads occur in some cases for surface mount pads on the solder mask or paste mask layer of your PCB. Rather than generating the pad as one solid object in the associated Gerber file, your CAD software might output a cluster of smaller vectors that together form the pad. This issue can be handled by Bittele’s production team, but requires some specific engineering attention and therefore additional time during manufacturing. To make things more efficient for everyone, we recommend setting your software to generate “Flash Pads” instead of “Vector Pads”.

If you double-check all of the above points before making your design submission to Bittele, you can guarantee the most efficient possible quoting and PCB production process. As previously mentioned, our team will catch the vast majority of Gerber files issues before they can impact the production of your boards. This is one of the main advantages to our meticulous quality standards for PCB Assembly in Canada. Still, the process works best when all parties work together for the best possible build.

If you find yourself with any remaining questions about your Gerber files, or to place an order with Bittele Electronics, you can Contact Us any time! We can be reached via email at sales@7pcb.com, or toll-free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English