TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Benefits of Flexible PCBs and its Applications

Introduction

Flexible printed circuit boards (flex PCBs) are interconnect structures built on ultra-thin, bendable substrate materials. Unlike rigid boards, flex PCBs can be folded or shaped into three-dimensional (3D) configurations, enabling compact and space-eƯicient designs. This flexibility makes them ideal for high-density interconnects in constrained spaces. As shown in Figure1, flexible PCBs are primarily used for interconnection rather than component mounting in electronic devices.

Advantages and Disadvantages of Flex PCBs

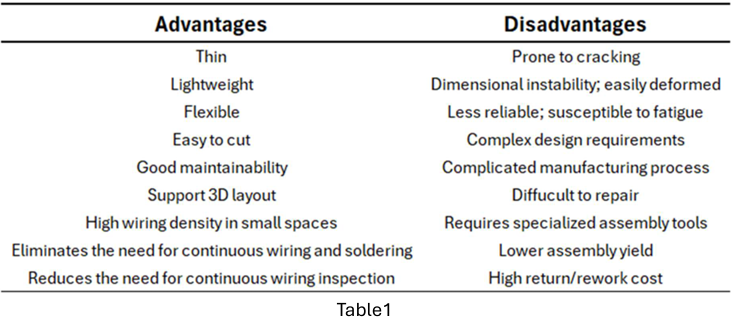

The primary advantages of flexible PCBs lie in their thinness and bendability, which oƯer unique benefits not achievable with other interconnect technologies as shown in Table1.

These include 3D routing, compact assembly, and long-term dynamic bending with small bend radii, critical in applications where rigid boards fall short.

However, the small thickness and flexible structure also introduces challenges. Improper use of flex PCBs can negatively impact manufacturing yield, reduce production eƯiciency, and significantly increase costs. Therefore, a careful trade-oƯ analysis is essential when integrating flex circuits into packaging systems.

Cost Considerations

Compared to rigid PCBs or flat cables of similar size, flex PCBs are generally more expensive. To achieve 3D interconnects, flex circuits often require larger surface areas than rigid boards. While this increases PCB fabrication costs, the overall system cost may still be lower than using multilayer rigid boards with connectors and cables.

When evaluating cost, it’s important to consider the total system cost, including connectors, cables, and assembly labor when comparing rigid and flex solutions. Although flex PCBs have higher unit costs, they can reduce the need for additional components and simplify assembly, making them cost-eƯective in many applications.

That said, unless 3D routing is essential, designers should carefully assess the need for flex circuit especially in cost-sensitive consumer electronics. Flex PCBs are best suited for applications where their unique properties are indispensable, such as tight-space constraints routing, lightweight designs, or products requiring long-term bending.

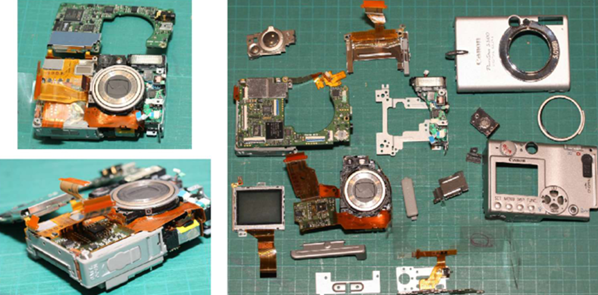

For example, Figure2 illustrates the use of flex PCBs in a digital camera. In this case, a combination of one multilayer rigid board and over a dozen flex circuits was used to optimize layout and control overall system cost, demonstrating flex PCBs as the most eƯective technical solution.

Applications of Flex PCBs

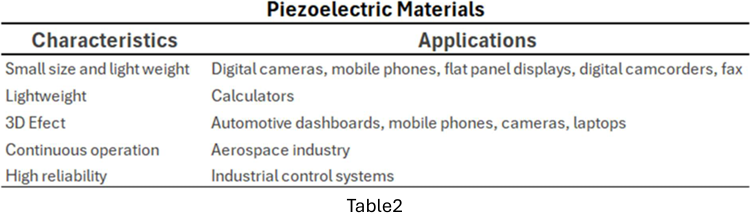

As mentioned, flex PCBs are ideal for scenarios where traditional interconnects fall short. Table2 outlines their characteristics and application areas. Typical use cases include portable electronics such as smartphones, digital cameras, automotive dashboards, and handheld computing devices where reliable 3D interconnects are required in compact spaces.

In some cameras, multiple flex circuits are compact into a very small area. Flex PCBs are also used in devices with movable mechanical parts, such as laptops, PDAs, and other foldable or hinged electronics. Products like hard drives, compact printers, and flip phones benefit from the long flex life of dynamic bending structures.

Additionally, rigid-flex PCBs which combine rigid and flexible layers are widely used in aerospace and compact consumer electronics. These hybrid boards reduce routing space and improve interconnect reliability, meeting the demands of complex, space-constrained designs. Meanwhile, manufacturers are also working to lower the production cost of flex circuits for broader adoption in consumer markets.

For additional information about our capabilities, or to submit your PCB design files for an oƯicial quotation, please do not hesitate to contact us at your convenience. You can reach us via email at sales@7pcb.com or by phone at 1-416-800-7540.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English