TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Tips for Automatic PCB routing in PCB Design

The auto-router feature is a great tool that most PCB design software have that can save the designer some time. The auto-router systematically routes the connections that were made in your schematic and saves you the time of having to manually doing it yourself. Here are a few pointers when using the auto-router for your projects.

1. Review Our Requirements And Capabilities

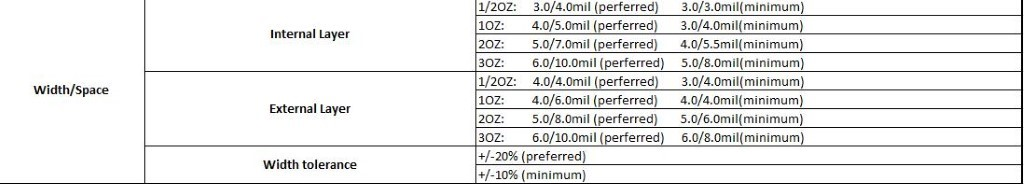

Make sure to set the clearances’ for the trace width, and trace spacing before using the auto-router feature. Figure 1, pictured below, shows our capabilities. Please refer to our PCB manufacturing guidelines and our DFM (Design for Manufacturability guide) for more information.

2. Optimize the placements of parts on your board

Before using the auto-router, make sure all the components are placed in a space-effective manner. Depending on the clearances set for the project, you may have to space out the components on the board to avoid having any over lapping traces or a low success rate when using the auto router.

3. Acute angle Routes

The auto-router may create sharp angles when routing, it is best to manually fix these traces yourself. Traces which are about 45 degrees, and have smooth angles are optimal. The issue with having sharp 90 degree traces is during PCB fabrication, in the etching phase, they may get etched narrower than the standard trace width. This could potentially result in short circuits in these areas.

4. Route the more complex components yourself

Use the auto Router for some of the easier components parts of the board and manually route the more complex ones yourself.

5. Double check the Connections

it’s always a good practice to review all the connections that you made to ensure there are no mistakes.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English