TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Electro-less Nickel, Immersion Gold (ENIG)

Electro less Nickel/Immersion Gold (ENIG) is a double-layer metallic surface finish that is composed of a very thin layer of gold, applied over a layer of nickel. A nickel layer is first plated onto the PCB copper pads using an electroless process: a controlled chemical reaction. A gold layer is then applied on top of the nickel layer using immersion methods to cover any exposed pads and traces.

The top layer of gold in an ENIG finish protects the nickel during the storage period, thus providing excellent overall shelf life. This finish also creates a very flat surface, which is ideal for mounting parts such as Surface Mount Devices (SMDs) and Ball Grid Arrays (BGAs). ENIG is a highly popular surface finish option due to its durability and planar qualities, as described above, as well as the high electrical conductivity of gold. These three aspects of the ENIG finish make it a convenient solution for all types of projects and industries, from project specific demands including High Power PCBs and High Speed PCBs, to external influences such as High Temperature PCBs.

Typically, an ENIG surface finish is only applied after a Solder Mask layer is applied; this avoids needlessly increased cost that would result if all copper surfaces were plated with gold. If you choose Bittele’s Complete PCB Assembly option, we can adjust our PCB Assembly Process to take care of stencil preparation concurrently with surface finish application; that way, PCB Assembly can begin as soon as the finish is applied and the boards are tested.

As a result of the many advantages listed above, ENIG has become the most highly-used finish in the PCB Fabrication industry since the growth and implementation of the RoHS regulation. Unfortunately, such great advantages cannot come without drawbacks, and for ENIG the biggest drawback is its complex and sensitive application procedure. If proper Quality Management is not followed for this procedure, issues such as "Black Pad" may occur. Black Pad is a buildup of phosphorous between the gold and nickel layers, which may result in fractured surfaces and faulty connections. To ensure that you never have to worry about these issues on your ENIG boards, Bittele provides testing and inspection at every stage of both PCB Fabrication and PCB Assembly, utilizing methods such as Electrical Testing, Automated Optical Inspection (AOI), and repeated Visual Inspection.

Pros

|

Cons

|

|---|

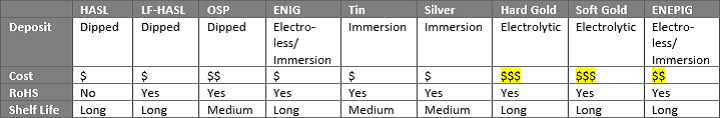

We at Bittele offer Electroless Nickel Immersion Gold (ENIG) finish as one of our PCB options. The table below lists our available surface finish options for your reference, along with some basic associated information for each finish.

If you still find yourself with any questions about Immersion Tin or any other surface finish, or to send along your PCB Design Files for an official quotation, please feel free to Contact Us at any time! Bittele is a PCB Assembly in Canada service provider, supplying top-quality PCB products and services to our clients worldwide, which includes helping you to determine which surface finish option is right for your project. To get in touch with one of our PCB experts today, you can send email to sales@7pcb.com, or call us toll-free at 1-888-812-1949.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English