TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

What is the difference between AOI and SPI?

In SMT (surface mount technology) assembly, AOI (automated optical inspection) and SPI (solder paste inspection) are two common inspection technologies. Although they both play an important role in quality control, their functions and applications are very different. This article will analyze the difference between AOI and SPI in detail to help readers better understand these two technologies.

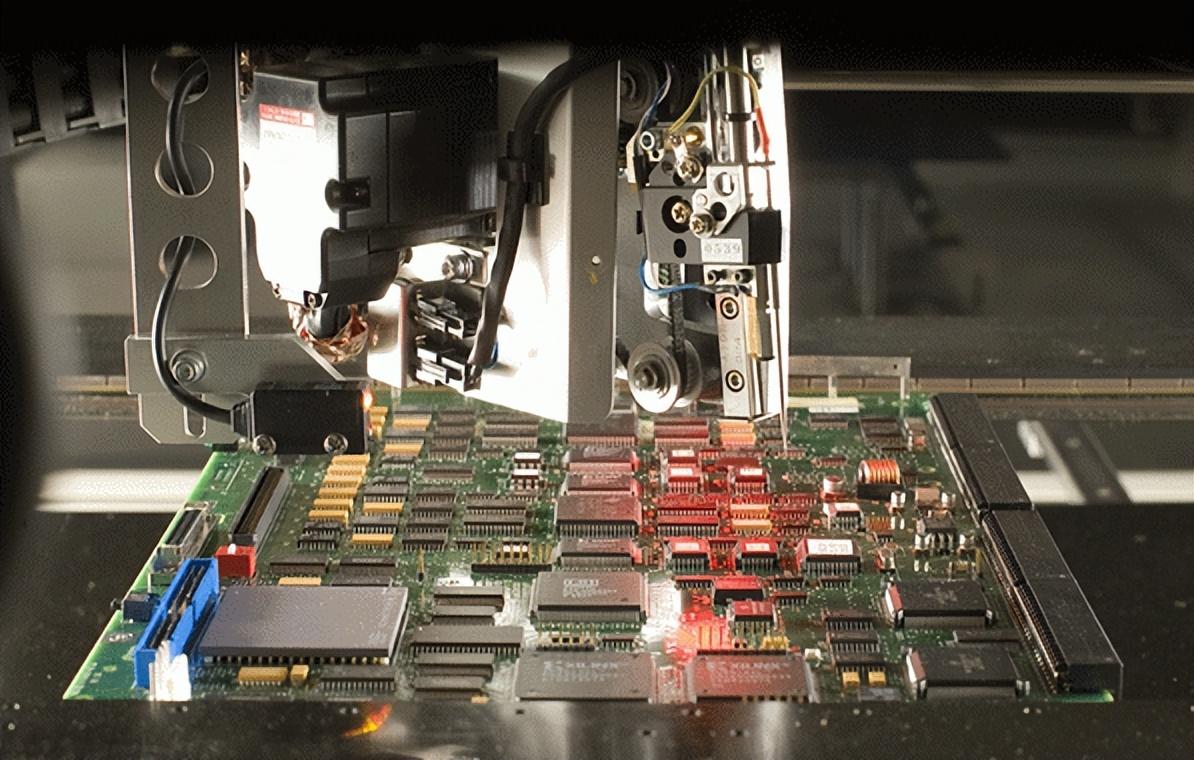

First, let's take a look at AOI. AOI is a technology that automatically detects the quality and correctness of electronic products through an optical system. It plays a key role in the SMT production line. The AOI system uses high-resolution cameras and image processing software to scan the components on the circuit board and compare them to the expected positions and features. By analyzing the image data, AOI can detect quality problems such as component position deviation, silk screen quality problems, pin short circuits, etc. Due to its high efficiency and accuracy, AOI has become an indispensable technology in the SMT industry.

In contrast, SPI is a technology used to check the quality of solder paste printing. In SMT assembly, a thin layer of solder paste must be printed on the circuit board to ensure that the components can be firmly attached to the circuit board. The SPI system uses a high-resolution camera and image processing software to scan the print quality and compare it with the expected position and features. By analyzing the image data, SPI can detect quality problems such as uneven solder paste printing thickness, lack of material, and excess. By promptly detecting and correcting these problems, SPI can ensure that the components on the PCB can be properly connected during the soldering process.

It can be seen that AOI and SPI differ in the objects and purposes of inspection. AOI focuses on the assembly quality and solder connection quality of electronic products, while SPI focuses on solder paste printing quality. Although the working principles and equipment of AOI and SPI are similar, their application scenarios are different. In SMT production, SPI inspection is usually performed first, followed by AOI inspection to ensure product quality.

In summary, there are obvious differences between AOI and SPI in SMT assembly. AOI is mainly used to detect assembly quality and solder connection quality, and SPI is mainly used to detect solder paste printing quality. They play an irreplaceable role in SMT production, ensuring product quality and production efficiency. By understanding and applying AOI and SPI technologies, manufacturers can improve product quality and minimize defects and losses.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English