TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

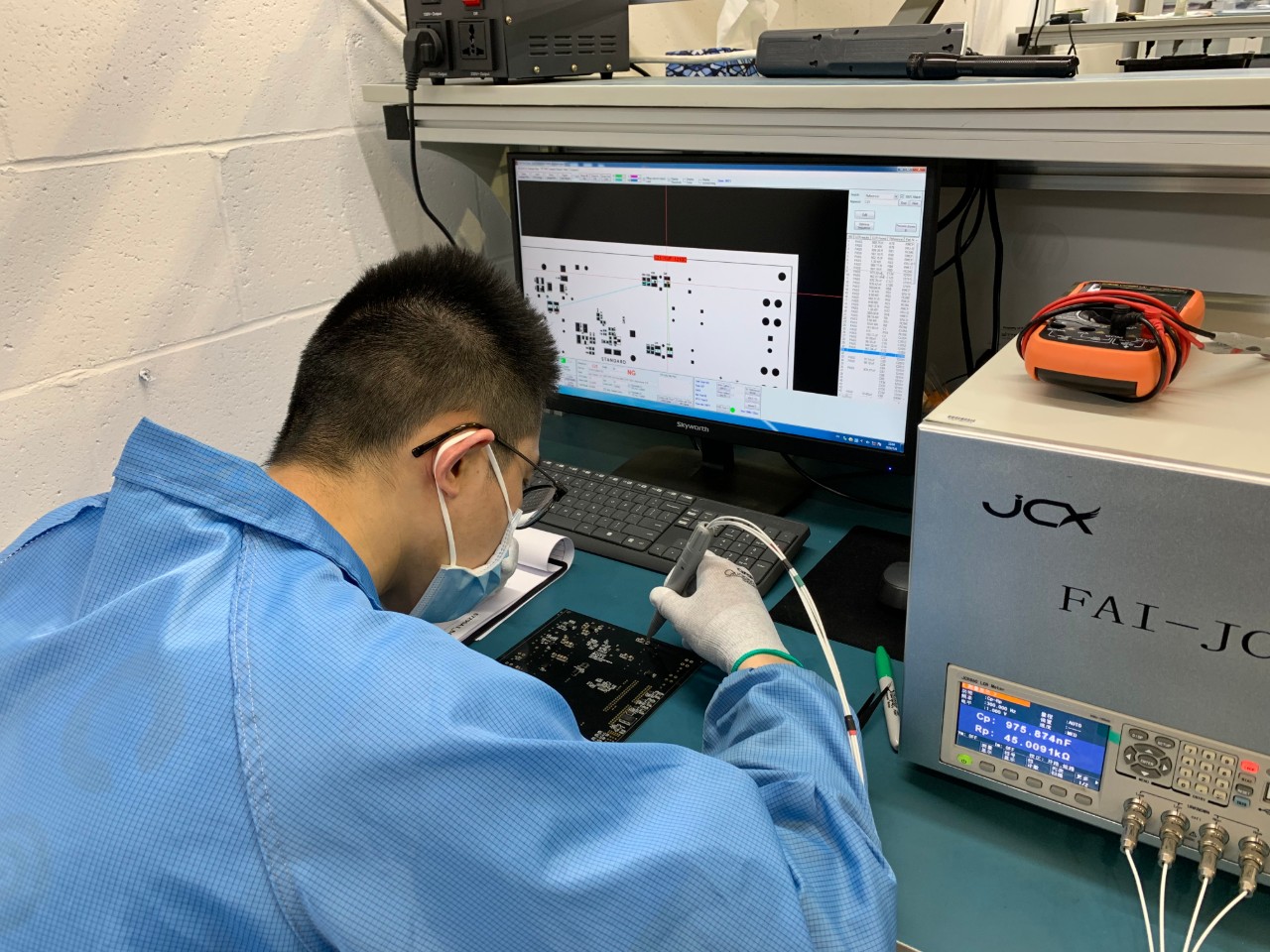

First Article Inspection in the PCB Assembly Process

Bittele Electronics offers first article sampling services, to ensure our customers are satisfied with our quality of work before proceeding to full production. This service would not be possible without first article inspection (FAI), which involves the inspection and testing of the very first PCB to go through each stage of the assembly process. This master circuit board is given special priority, as it is the standard which we use to ensure our assembly equipment has been calibrated, programmed, and is functioning correctly. First article inspection incorporates the parts management, 3D solder paste inspection (SPI), automated optical inspection (AOI), 3D AOI, instrumentation, parts orientation and reference verification processes.

Our qualified assembly technicians will verify that all components for each order match the customer’s design and BOM. Once this is done, after each step of the assembly stage, our quality engineer will inspect the circuit board visually, through automated SPI and AOI machines for any issues in solder paste application and component placement. This will ensure that any possible maladjustments are caught and rectified immediately, before starting the complete assembly run.

Our quality engineer will then conduct measurements with our state-of-the-art FAI system, to ensure that every part has been placed correctly, before finally soldering them onto the printed circuit board. The FAI system generates a report, which our engineer and technicians use to determine if the PCB was assembled correctly, or if further adjustment to our manufacturing equipment is necessary. And once the board has been finally soldered, it will be subjected to visual inspection, X-ray inspection (for BGA components) and functional circuit test. If any issues arise during assembly, our FAI process will allow us to adjust our manufacturing equipment accordingly. After passing all quality checks, we will provide high resolution images of the board to our customers for approval, before completing the order.

Our first article sampling service grants customers the opportunity to assess the quality level of their PCBs, before proceeding to full production. Through this service, customers will receive a small sample of PCBAs for approval before the rest of the order is assembled. The exact number of samples can be determined with your sales representative during the quoting process. At Bittele, we will go the extra mile to make sure your orders are fulfilled to your satisfaction, with only the best results.

English

English