TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Conformal Coating

As your full turnkey PCB assembly supplier , Bittele offers competitive conformal coating services to fulfill all your board-level needs. With the capability to perform conformal coating services at both our facilities in Canada and China, we use a wide variety of coating materials with an automated selective coating process, to maintain high quality, reliable, and consistent results.

As with all our turnkey services, all PCBs are first assembled and undergo Functional Testing, as rework becomes particularly difficult after the conformal coating is applied.

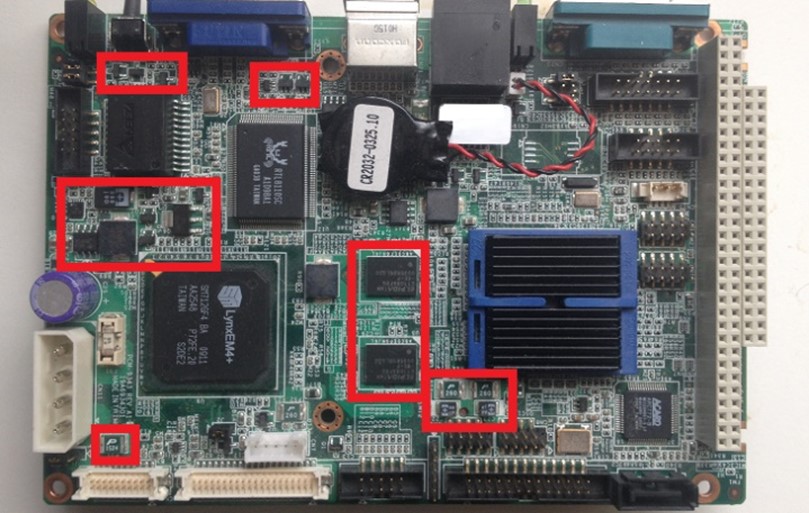

Then, before conformal coating can be applied, our team of engineers verify all areas of the circuit board that are to receive conformal coating, as provided by the client. Using this information, our engineers will then mask all other areas of the board that are not to receive conformal coating, to protect from overspray. The coating material is then prepared, while our selective conformal coating application system is configured to spray coating material to a default thickness before further adjustments are to be made.

The prepared coating material is then loaded into the application system before a test plate is fed into the system. The system then applies conformal coating onto the test plate, which is then dried and checked for the correct coating thickness with a micrometer screw gauge; if too much, or not enough coating material was applied, the plate is then cleaned of any coating material, the application system reprogrammed with the correct thickness and the plate recoated.

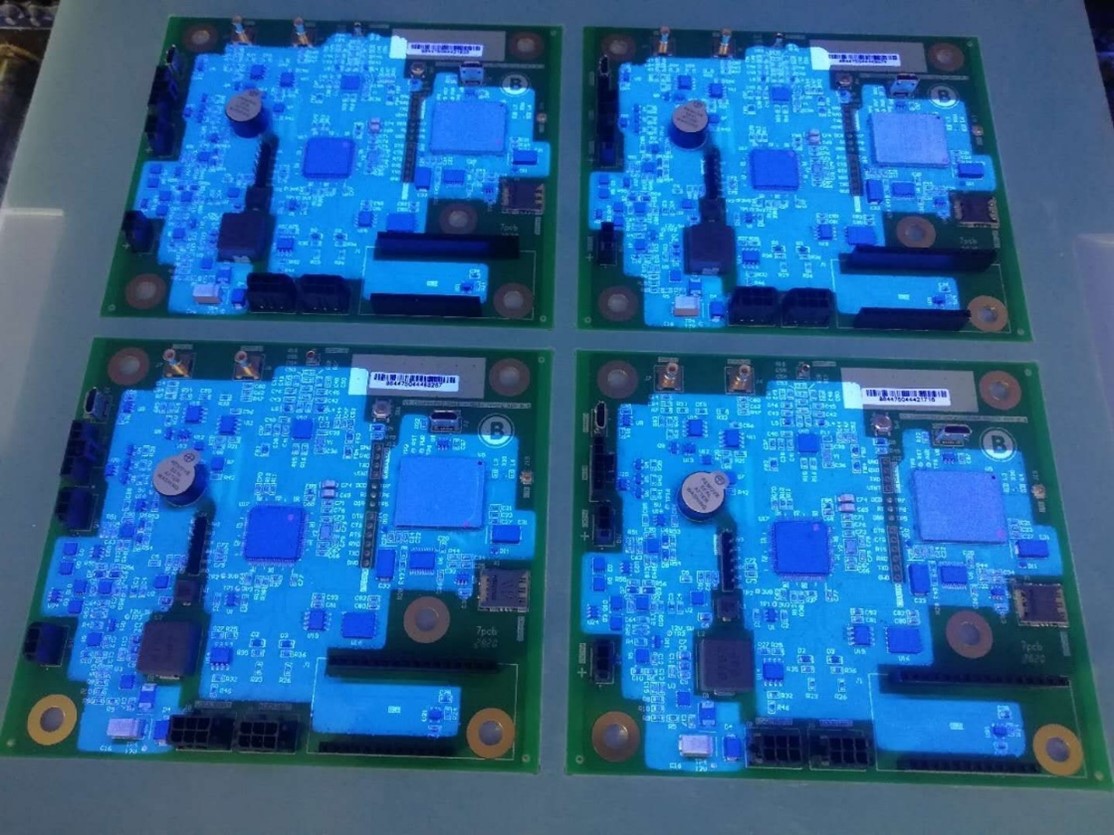

Once the application thickness is satisfactory, the plate is then left to cure, before being examined under an ultraviolet light, to ensure full coverage of the plate. Only when these parameters meet the client’s requirements and our stringent quality standards, will we proceed to program the application system with PCB coordinates and begin applying conformal coating onto the boards. The coating thickness is then measured every 4 working hours during the application process, before the boards are dried and checked for proper coverage under ultraviolet light. The boards are finally left to cure over a 24-hour period.

We at Bittele offer urethane and acrylic based conformal coatings to suit most of our client’s needs. For PCBs that operate in critical environments, we utilize urethane-based coatings, namely ELPEGUARD SL 1301 ECO-FLZ for orders assembled in China, and MG Chemicals MG4223F for orders assembled in Canada; they offer very good resistance against moisture and condensation, and excellent protection against corrosion and abrasion. For circuit boards operating in less harsh conditions, however, we utilize acrylic resin coatings, namely ELPEGUARD SL 1307 FLZ for orders assembled in China, and MG Chemicals MG419D for orders assembled in Canada; they can be soldered through for rework purposes and are also removable with a thinner. Regardless of which material our clients choose, all are RoHS compliant, IPC-CC830B tested, dry from 10 to 20 minutes and can be applied to a thickness of between 25 and 75 micrometers. Upon request, we can also provide silicone, epoxy and paracyclophane based conformal coatings.

All we need to accomplish this are Gerber files (preferably in RS274-X format,) the bill of materials and specification documentation (including the required coating thickness, as well as drawings or images indicating any areas to be masked). The number of areas that require masking, also known as blocks, affect the coating cost. Board size, as well as the number of sides to be coated, also affects the coating cost and lead time.

Quality matters; do not settle for less. For any inquiries relating to your conformal coating needs, feel free to contact us. Our team of experts are always glad to assist and accommodate for any of your requirements.

English

English