TURN-KEY PCB ASSEMBLY: BITTELE ELECTRONICS

PCB MANUFACTURING AND ASSEMBLY

Full Turn-Key PCB Manufacturer

You can quickly get quotes and order PCB fabrication and assembly using our online system. Take advantage of exclusive automatic discounts with our tool. Our BOM pricing tool ensures you receive the lowest price for your order.

START A TURN-KEY PCB ORDER

Impact of copper thickness

Copper thickness is the single most commonly changed property of a PCB (besides the dimensions of a PCB), however most do not think of the other properties of their board when changing the copper weight. Thus a simple copper weight change can often cause many unexpected required changes in other properties of a board.

At Bittele Electronics we aim to be as transparent as possible with our DFM/DFA Reviews, this article is an attempt at providing an in depth explanation to some of our questions and statements regarding copper weight and how changing it affects the DFM/DFA Review process.

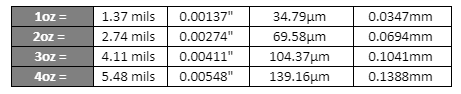

To begin with the most common representation of copper on a PCB layer is in ounces. 1oz of copper is the same as 1.37mils, where 1.37mils is the thickness of a single ounce of copper being pressed flat and spread over a one square foot area. At Bittele Electronics we assume that the copper weight of a layer is 1oz unless stated otherwise.

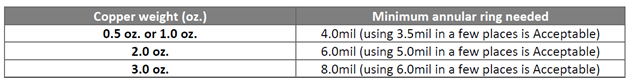

A change in the copper weight of a board will change the minimum annular ring needed for a via. Annular ring size is an important PCB design specification since it helps produce a reliable electrical connection to a via even when the drilled hole is not perfectly centered.

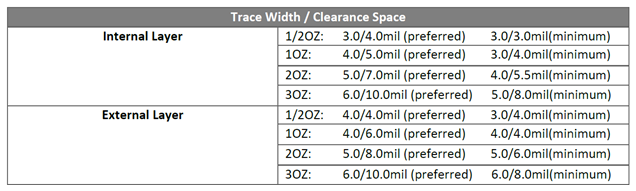

The width and spacing of traces is highly sensitive to the copper weight on the specific layer. This in turn affects the stack up of the board and impedance control calculations of the traces as well. Thus a change in copper weight can have a cascading effect for tight trace width/spacing and impedance control.

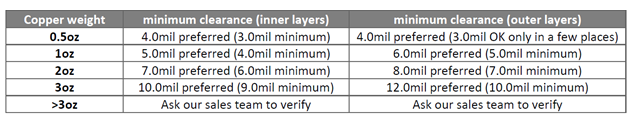

The copper weight of a layer will also affect the minimum conductor clearance required on that layer. The heavier the copper weight is the deeper the etching is as well (and thus the deeper the effect of undercut), therefore the conductor clearance needs to be widened in order to compensate.

One of the most obvious changes that changing copper weight will have to your project is simply cost. The higher the copper weight the more copper is required for a single layer, factor in multiple layers, the area of the board, and the number of boards and there could be quite a significant increase in the cost of your project.

Related Articles:

Please briefly describe the information you are seeking in the search bar below.

English

English