The Role of Copper Weight in Circuit Board Fabrication

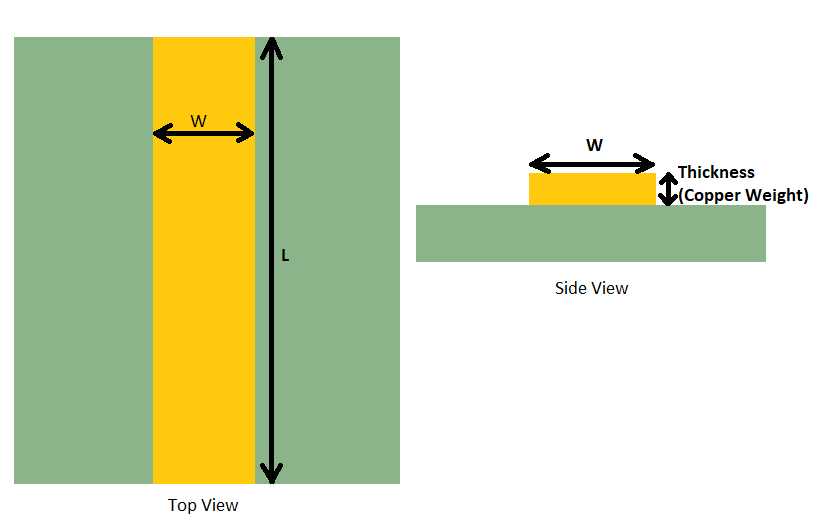

There are many different types of PCB Fabrication projects that require specific copper weights for a variety of reasons. At Bittele Electronics, we offer a generous selection of copper weights to suit your specific needs. From time to time, we receive questions from clients who are unfamiliar with the concept of copper weight, so this article is intended to address those concerns. Additionally, information about the effects of different copper weights on the PCB Assembly Process is included below, which we hope will be useful even to those clients who are already familiar with the concept; a firm understanding of our processes allows you to better plan for the manufacturing schedule and overall cost.You can think of copper weight as the thickness or height of your copper traces, the third dimension that is not taken into account by the copper layers data of your Gerber Files. The measurement is given in ounces per square foot (oz / ft2), where 1.0 oz copper translates to 1.4 mil (35 μm) thickness.

Heavy Copper PCBs are commonly used for power electronics devices, or any device that might be subjected to harsh environments. The thicker traces allow for greater durability, and also allow the traces to carry a larger amount of current without trace length or width being increased to absurd levels. On the other end of the equation, lighter copper weights are sometimes specified to achieve a specific trace impedance without requiring an extremely small trace length or width. As such, you can see that Copper Weight is a required field in our Trace Width Calculator.

The most commonly used copper weight value is 1.0 oz. finished, which is suitable for the majority of projects. “Finished” in this context, refers to the fact that the initial copper weight will be plated up to a higher value during the PCB Fabrication process. When specifying your desired copper weight to our sales team for quotation, please indicate the finished (plated) value of copper weight that you require.

At Bittele Electronics, we offer any copper weights up to 1.0 oz. as of our Standard Cost PCB Options, meaning no additional charge will be added for any weight up to that standard. For copper weights above 1 oz., there will be some additional cost and lead time required. You can use our Online PCB Fabrication Calculator to get an idea of how this aspect of the board will affect the cost and lead time of your project. Please note that for copper weights of 4.0 oz. and above, we will need to have our engineering team review your design files before we can fully develop your quotation, so please send us your preliminary files for estimate as soon as possible.

Higher copper weight values introduce additional cost and lead time not only due to the additional copper itself, but also for additional shipping weight, as well as time required for labour, process engineering, and Quality Assurance. These additional measures are necessary first of all because the additional copper cladding on the laminate will require more time for etching, and must observe specific DFM Guidelines. The copper weight of your board will also affect its thermal profile, causing your board to absorb heat significantly more quickly during the Reflow Soldering stage of PCB Assembly.

We hope that this information has helped to familiarize you with Bittele’s various copper weight options and the impact that this selection might have on your PCB project. If you still have any questions about copper weight, or to get started on your PCB project with Bittele today, please Contact Us any time using our email sales@7pcb.com, or call us toll-free at 1-888-812-1949.

Related Articles:

- Heavy Copper PCB

- How Copper Planes and Fills Affect PCB Fabrication and PCB Assembly

- What are the Factors Affecting the Cost of PCB Production?

- Impact of copper thickness

- How Copper Planes and Fills Affect PCB Fabrication and Assembly

Search articles: