How to get real-time thermal data for a PCB?

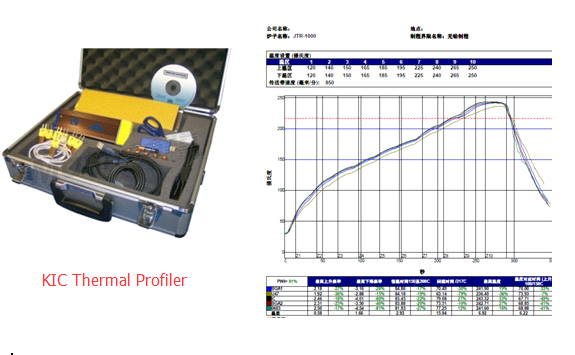

Although there is a thermal data testing function for our reflow oven, Bittele Electronics still uses a high-end, off-line, KIC thermal profiler as our key instrument for optimizing the reflow profile for every board.

Although there is a thermal data testing function for our reflow oven, Bittele Electronics still uses a high-end, off-line, KIC thermal profiler as our key instrument for optimizing the reflow profile for every board.

These are the benefits of using an off-line thermal profiler:

- The off-line profiler uses standard type K thermocouple connectors. It goes through the oven with target board. So, you don’t need to prepare long wires to connect each thermocouple.

- It provides better data acquisition to precisely identify what is going on with each thermal profile and process in the production line.

- Thermal profile data are conveniently transferred to a computer via a USB connection. So, a process engineer can analyze and check the data for solder joint quality easily.

- Data Intelligence software such as Navigator Power is able to identify the best oven setup in seconds. A Process Window Index (PWI) is introduced to check if the profile is getting optimized -- the lower the PWI number, the more centered the profile is within the process window. A process engineer can use this result to manually adjust the profile easily.

Related Articles:

- Thermal Mass in PCBs and How Bittele Creates it’s Thermal Profiles

- Why does Bittele Use a 10 Zone Force air convection reflow oven?

- Under what conditions do you set different temperatures for the TOP and Bottom heating elements of a reflow oven?

- Reflow oven zone temperature set up and thermal profile

- How to attach a thermocouple to a target PCB?

Search articles: